High-quality and customer adapted industrial freezing and chilling systems.

Scanico delivers innovative solutions to customers all around the world, focusing on development and manufacturing of high-quality industrial freezing and chilling systems. Scanico’s systems are designed to ensure high productivity and finished food products that match the highest quality demands of our customers. Scanico is a leading supplier of highly efficient impingement (patented) and spiral systems – freezers, chillers, proofers and steamers/ pasteurizers for all further processed product. Each system is custom-made and designed in accordance with customers’ requirements. Scanico technology adds value to production plants throughout the world. Each Scanico system is designed for continuous freezing, chilling, steaming or proofing of a wide range of applications – according to the specific nature of the customers products – and ensuring that the products match the quality demands from the customers. Scanico is famous for its

- Unique airflow resulting in fast freezing

- Energy efficiency

- Sanitary design

- Highest production uptime between defrost

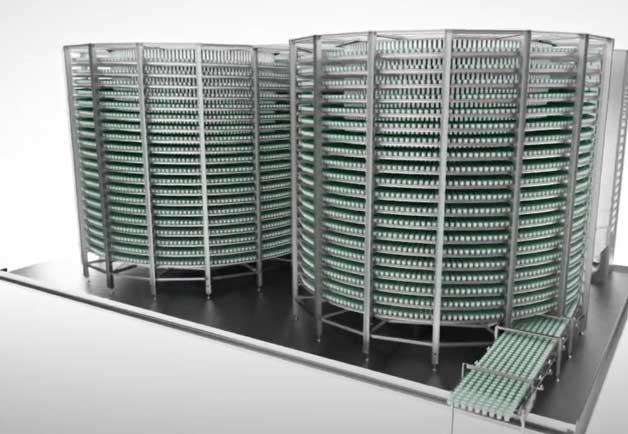

Spiral Proofer

The Scanico Spiral Proofer is designed for continuous proofing of a wide range of bakery products, such as Danish pastry, croissants and other types of dough products. The environment is constantly monitored and both temperature and humidity are automatically adjusted to the desired level, optimizing the fermentation process.

The temperature and the humidity are accurately controlled.

Temperature adjustable from +20°C to +35°C.

Relative humidity can be controlled up to 90%.

- Humidity: By water mist/steam

- Temperature: By steam / electrical

- Air speed control

- Proofing time adjustuable

Spiral Cooler

The Scanico Spiral Cooler consists of a spiral arrangement built inside an isolated enclosure. The internal air is continuously cooled and circulated horizontally over the product. The Spiral Cooler is ideal for food applications where a fast and uniform cooling is required. The Scanico Spiral Cooler is often used as an ascending spiral cooler connected to an descending spiral freezer. The cooler is available as a Forced Cooler or an Ambient Cooler.

- Belt width: 400 mm up to 1400 mm.

- Belt types: Plastic belt / Steel wire mesh.

- Spiral layout: According to request.

- Drum: Single or double drum systems.

Spiral Freezer

The Spiral Freezers is suitable for almost any processing line. Extra strong belt supports make it possible to carry heavy products demanding a long retention time. The spiral freezer is the most flexible spiral solution and can be adapted to fit almost any processing line. Available as single or twin drum spiral freezer. The Scanico spiral freezers are characterized by:

- Individual design to fit your specific needs.

- A unique horizontal airflow.

- High yield, best product quality and shortest freezing times.

- Long production up-time between defrosts.

- Single or twin drum design.

Impingement Freezer

The unique double impingement airflow ensures a quick freezing time with minimum product dehydration and maximum product quality. The method of circulating the air enables almost 100% utilization of the belt area, providing maximum capacity in minimum space. The Scanico TwinImp (TI) is available with one or more belts in different belt widths and directions. The impingement tunnel are characterized by:

- Unique impingement design provides faster, more efficient chilling/freezing.

- Highest chilling/freezing capacity per square foot of floor space.

- For garlic breads and other savory bakery products.