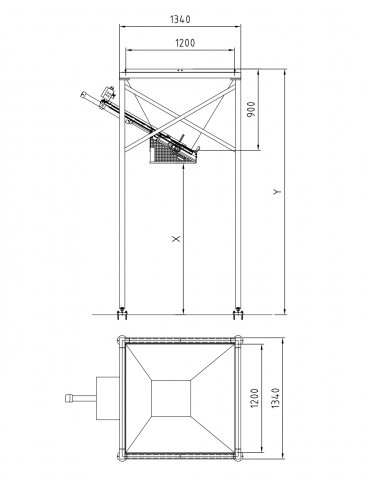

BULK HOPPER - BH

Bulk Hopper for standard dough divider SD180/300/600. Creates an even level in the divider/sheeter hopper which gives better weight accuracy..

Easy to Clean

Photocell

Features

Photocell controlled closing/portioning system. Gives automatic feeding into the divider.

Uncomplicated design. Results in reliable operation and less risk of production loss.

No need for special fastening devices to the divider. Possible to adapt to a wide range of dividers.

Stainless steel frame (option). Painted frame included.

Pneumatic controlled dough knife, width 400 mm as standard (other width on request).

Automatic photocell-controlled dosing/portioning device (compressed air required, min 6 bar) that creates an even dough level in the divider hopper and provides better weight accuracy.

Sliding plate on top of Bulk Hopper is included when shown on drawing.

Support bar between BL and BH is included when BL and BH is delivered together.

Design to work with dividers from other manufacturers (on request).

Key features

Feeding system

Photocell controlled closing / portioning system which gives an automatic feeding into the dough divider.

Specifications

Technical Specifications

Volume: 575 liter

Weight capacity: Dough up to 350 kg

Fuse (amp): 10A

Power supply: 0.3kW

Voltage: 1 x 230 V

Compressed air: 6 bar