Fossil Free Electric Heated Tunnel Oven

Sveba Dahlen delivers electric tunnel ovens to customers all around the world. Each oven is based on a basic concept and then adapted to the customer’s wishes and requirements. The ovens can be equipped with many types of belts, such as different kinds of wire mesh belts and solid steel belts. Electric heated ovens are produced in belt widths up to 4,2 m. They are produced in two different basic models, depending on the baking temperature to be used. “Normal temperature ovens” of up to 350ºC and “high temperature ovens” of up to 500ºC are available.

Energy efficient ovens

In the electrically heated oven the heating elements are installed directly in the oven chamber and the oven is separate regulated in each zone for top and bottom heat. This means that power is only used in the different zones when and where.

Features

Energy efficient ovens

In the electrically heated oven the heating elements are installed directly in the oven chamber and the oven is separate regulated in each zone for top and bottom heat. This means that power is only used in the different zones when and where.

“Normal temperature oven” up to 350°C. “High temperature oven” temperature up to 500°C (932F).

Available belt widths: 0,5 m to 4,2m (1,64 ft to 13,78 ft).

All ovens are designed by requested capacity, available lengths 4 – 75 m (so far) (13,12 – 246 ft).

Available belt types: Wire mesh belt and Solid steel belt.

Key features

Available Belts for Tunnel Ovens

Belts available for Electric Tunnel Ovens. Top left: Tight wire mesh belt for free standing bread. Top right: Open wire mesh belt for tin breads and trays.

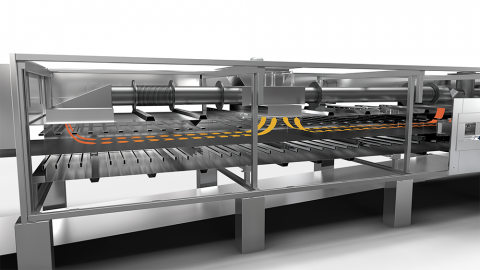

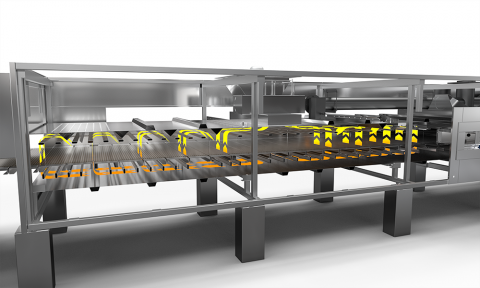

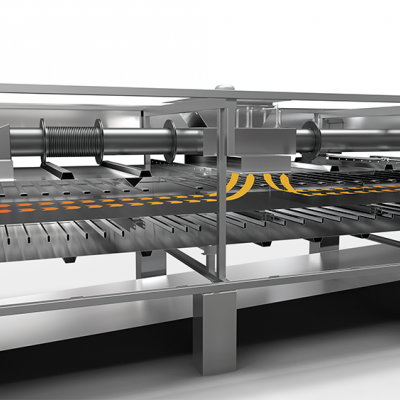

Air Flow Turbo Zone

Effective baking with the Air Flow Turbo Zone. Air flow above the belt and / or with repeated vertically Turbo air flow through the belt.

Control panel with touch screen

The HMI control panel with touch screen is easy to overview and operate. Control the top and bottom heat in all zones, recipes, alarms and more.

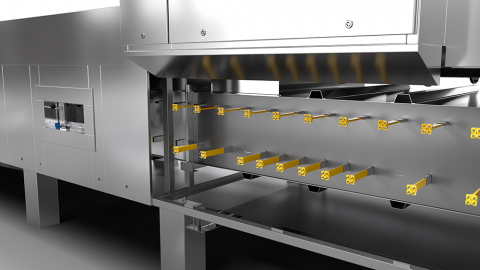

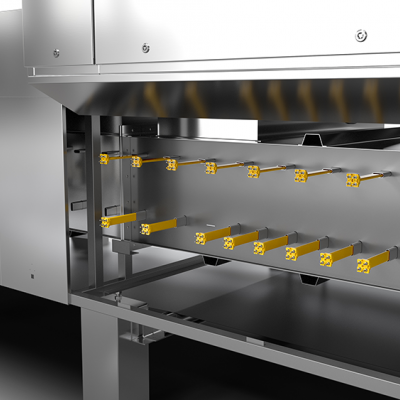

Heating elements

Our own high quality, specially designed heating elements, which always is adapted to the customers production, in sense of effect and quantity.