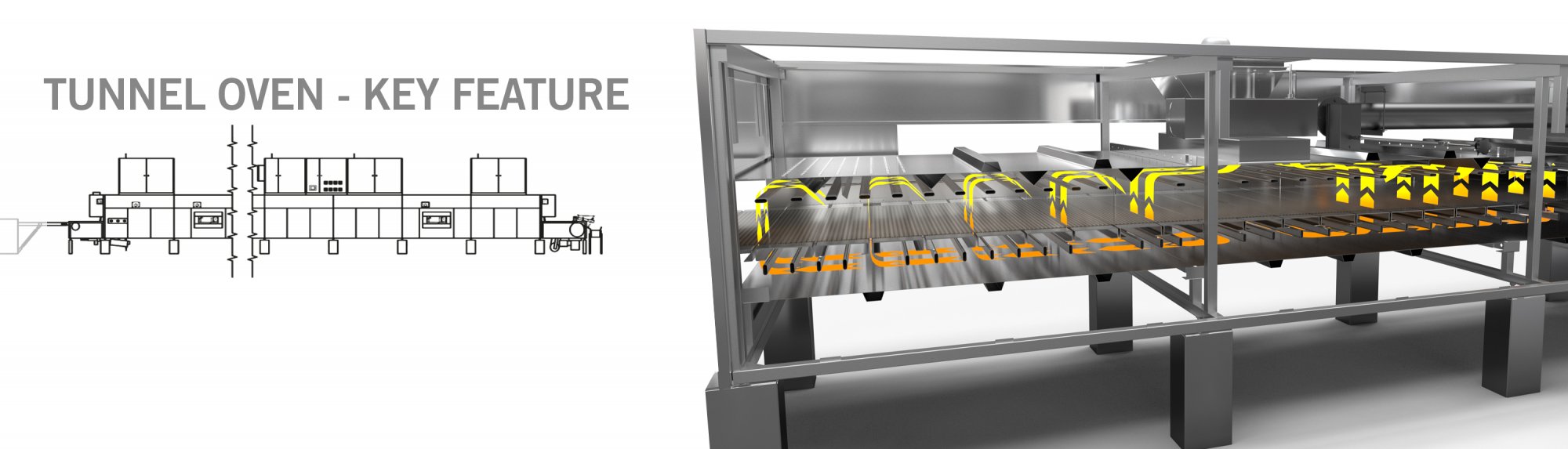

CUSTOMER ADAPTED TUNNEL OVEN SOLUTIONS

The Sveba Dahlen Tunnel Ovens is a concept built on sensibility to the customers demand, close communication, world-leading trademarks and well-trained personell at all levels.

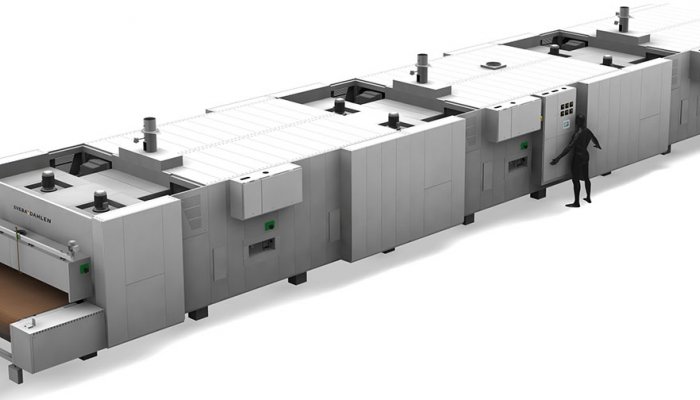

With over 400 tunnel ovens produced and delivered, many to some of the world’s most well known bakeries and food producers, Sveba Dahlen is firmly established as a leading manufacturer in the industrial bakery segment. Our production of tunnel-ovens began in 1955, and some of them are still in use today – after half a century of continuous production. The foundation of a Sveba Dahlen tunnel oven consists of carefully selected components that are designed for continuous production.

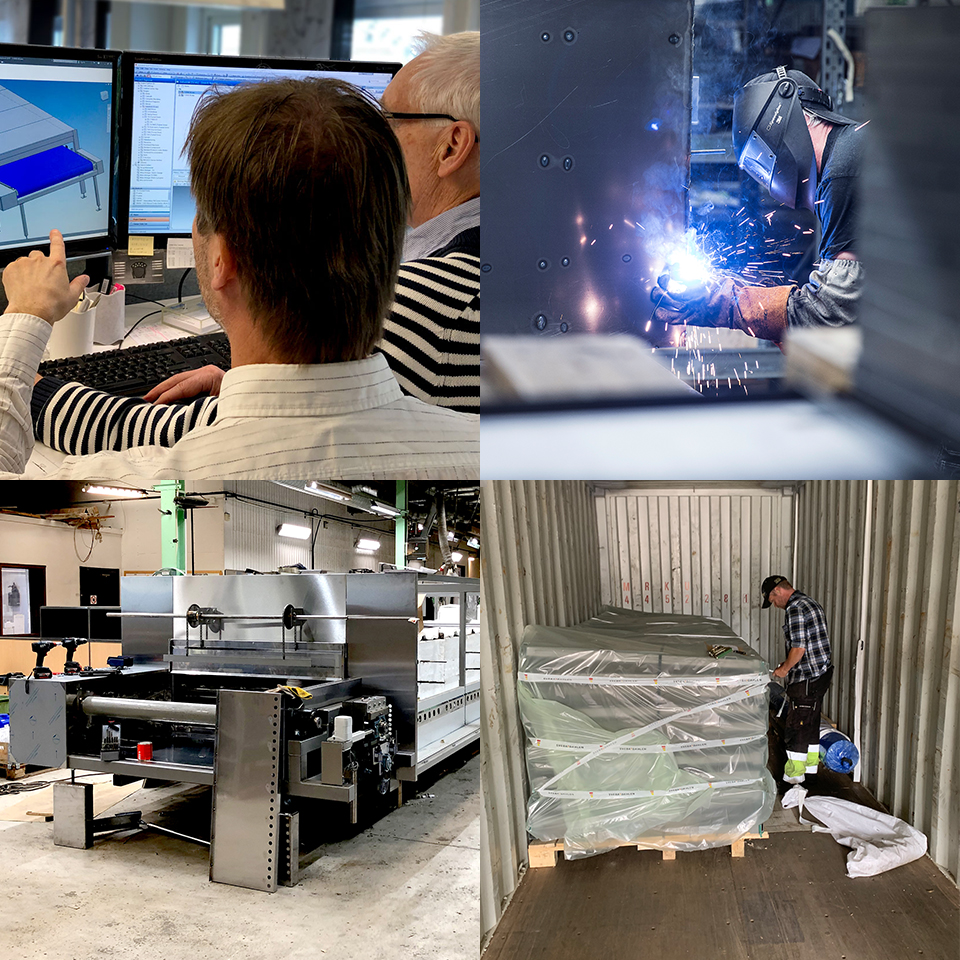

All in one place

The Sveba Dahlen Tunnel Ovens are made by our professional team in Fristad, Sweden. Here we control the process from start to finished oven. With all team members and processes in one place, from planning, to drawing, assambling and testing we can guarantee the quality of the product.

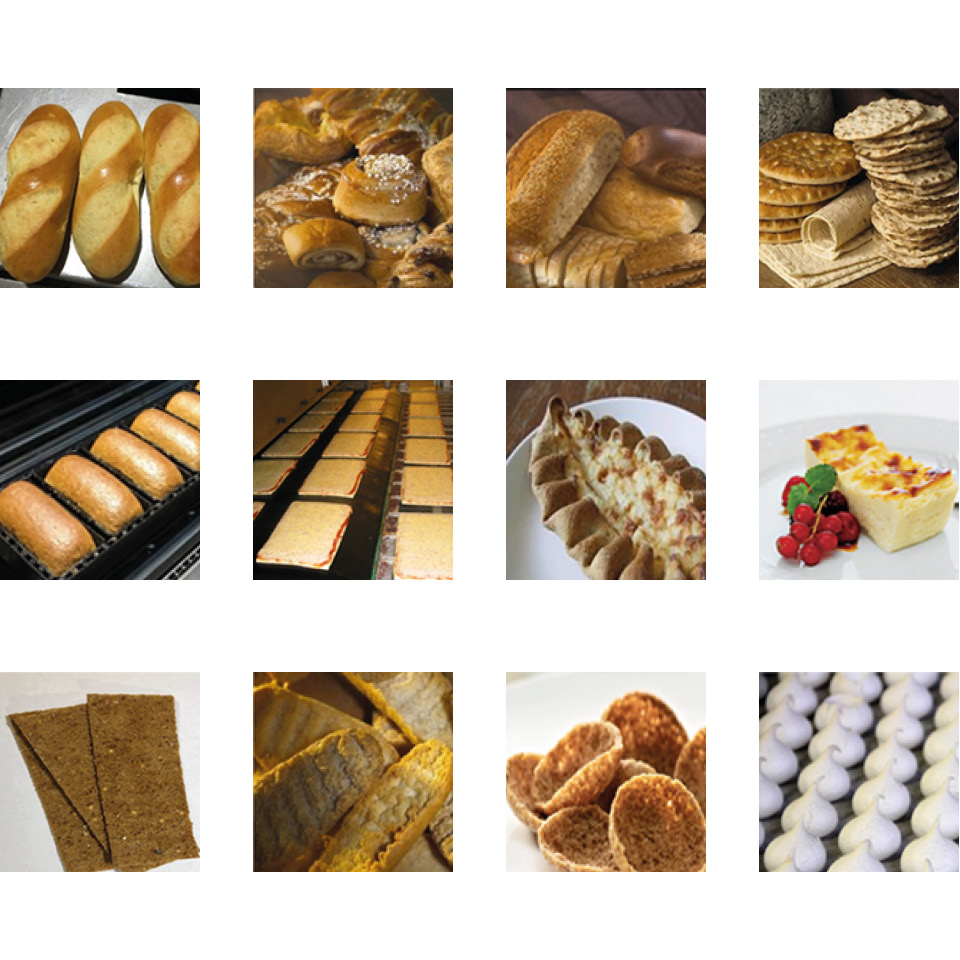

WIDE RANGE OF END PRODUCTS

For our standard industrial solutions, a wide range of products can be made. The machines and the ovens can be set-up to mange most kinds of bread and pastries. Above are some examples: Loafs, tin bread, baguettes, pan pizza, meringue peaks, buns and much more.

Tunnel Ovens and Industrial Ovens

All Sveba Dahlen Industrial Tunnel Ovens are adapted to meet the customers industrial needs. Both the Electrical and Indirect Gas heated ovens have the same user-friendly concept. Every zone is separately controlled, which gives the user maximum control of production. Desired temperature is set by temperature regulators, not by dampers and the top and bottom heat is set individually.

ENERGY EFFICIENCY IS THE FUTURE!

In these times of environmental awareness, energy efficiency and low environmental impact are the key. We are always looking for ways to minimize the energy consumption without affecting the baking results and only use materials which is mainly recyclable, most of the components in our machines can be recycled, since they mainly consist of steel and other metals. In the electrically heated oven the heating elements are installed directly in the oven chamber and the oven is separate regulated in each zone for top and bottom heat. This means that power is only used in the different zones when and where it is needed. This give the best possible energy efficiency in kwh/kg baked bread!

To receive the lowest possible energy consumption in a gas oven the patented Sveba Dahlen indirect heated oven use multi burner system for heating (one burner for top-heat and one for bottom heat, in each zone). This means that power is only used in the different zones when and where it is needed.