Proofer / Freezer / Retarder - F-Series F500

Reliable proofing results every time!

The F-Series F500 is a world class roll-in freezer proofer, retarder proofer and proofer. It is equipped with the latest technology to simplify work in the bakery and treats dough with the utmost care - no more dehydration or over-fermentation. The Dough on Demand function always gives you fresh dough ready to be baked. The F500 has carefully tested components and materials, providing an energy-efficient and reliable machine with a long life span. Together with the smart control panel and ergonomic design, the cabinet offers excellent results under heavy load in the bakery time and time again.

Features

Saves on both time and labor.

If the proofer is loaded the day before, the proofing process is complete by the time the workers arrive for the day.

Temperature control; yeast at the right temperature.

For the freezer-proofer and retarder-proofer variants, the F500 uses heating and cooling as needed, which means the temperature is controlled independently of the temperature outside the unit. In other words, it is possible to proof to a temperature of e.g. 15°C / 59°F, even if the room temperature is 40°C / 104°F.

Dough On Demand.

Dough on Demand proofs the dough at a low temperature over a long period of time.

Once finished, it cools and preserves the dough. The ready-to-bake dough can be preserved for up to 10 hours. The dough can then be taken out and baked off when needed by the store - fresh bread at any time!

Delayed proofing.

The F500 automatically cools down ready-proofed products if they are not taken out of the cabinet in time. This reduces the risk of overproofing.

User-friendly touch function control panel.

The control panel is easy to use and is ergonomically placed on the door. It controls all processes in the cabinet and ensures the dough is protected against drying out and is handled as carefully as possible. This gives the baker greater freedom and the ability to adjust times and settings to suit their workday and pace.

Quick and easy installation.

Compact and stable cabinet design – easy and quick to install, which means less annoying interruptions for other production, and the bakers can quickly start using the cabinet.

Energy efficient.

The walls of the cabinets are also insulated with tight-fitting 80 mm of polyurethane foam with unsurpassed insulation properties, retaining the heat/cooling. The doors are robust, insulated with large double glazed windows which give a great view into the cabinet. When the doors open, fans and humidifiers stop automatically, thereby reducing energy consumption and improving the working environment.

Easy cleaning.

Simple design with large surfaces and no unnecessary joints and frames makes the F500 easy to clean. The ceilings and air ducts can easily be dismantled without tools, in order to clean behind them.

Low ramp.

A low ramp and low floor make it easy to roll the racks in and out. The ramp has closed sides which means that it is harder for dirt to get underneath; it also has handles on the sides to make it easier to clean in front of the cabinet.

Sound and light signals.

A two-tone sound signals when a program is finished or action needs to be taken. Also available as a light tower (option).

Control Panel

User-friendly touch panel that streamlines and simplifies the work in the bakery. The control panel supports Dough on Demand, automatic programs and manual operation. Important functions such as humidity, temperature, cooling and fan speed are controlled based on needs and requirements. The touch panel comes with pre-programmed default settings so that you can start using the cabinet directly. Screen size: 7 inch.

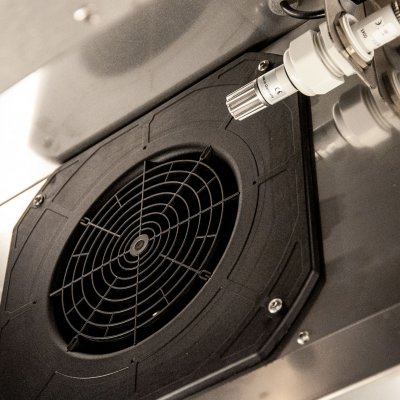

Demand-controlled fans

Fan speed is controlled as needed to process the dough so just the right amount of air is circulating inside the cabinet. Parameters such as cooling, heating and humidity control the fans in each program phase, running the fan at just the right speed. Heat and humidity are pulse controlled to facilitate precise climate control. This control also provides an optimal proofing process along with a more energy efficient and quieter cabinet.

Specially-designed air distribution channel

A specially-designed air distribution channel in the rear wall of the cabinet distributes the air very effectively. This results in gentler, more even air distribution with both falling and rising air. This leads to a more even proofing result without dehydrating the dough.

Floor

The F500 HIJ (Proofing) and HIK (Retarding-proofing) are supplied without a floor as standard. HIF (Freezing-proofing) comes with an insulated heated floor that counteracts freezing damage to the underlying floor and keeps it dry and free from condensation.

Robust insulated doors

Self-closing doors equipped with high quality hinges and ergonomic, rounded handles, as well as well-insulated double glazed tempered glass windows. Sensors on the doors start/stop the proofing program, turn on the light, and stop the fans when the doors are open – all to protect the dough, reduce energy consumption and contribute to a better work environment. If the doors are opened past 90 degrees, they will remain in the open position. Proofer equipped with a door (1000 mm wide), available with either a right or left hung door.

Materials and components

Robust materials, and its top-quality, tried-and-tested components guarantee the cabinet’s performance and long service life. Stainless-steel drain valve and baking trays will withstand the stress and strain of bakery production time and time again. The F-Series is made in Sweden.

Easily monitored process

Large insulated windows with double glazing and vertical LED strips with daylight effect give the user a good overview of the proofing process on all the sheets in the rack trolley. The light starts automatically for the proofing process and can be started from the control panel for the retarding-proofing and freezing-retarding programs. Detailed information such as time, temperature and humidity are displayed on the cabinet’s control panel.

High quality compressor

The F500 HIK retarder-proofer and HIF freezer-proofer include a high quality compressor. Installation requires cooling specialist technicians. The compressor must be positioned max. 10 meters from the cabinet.

Temperature and humidity

F500 HIJ:

Ambient temperature to +45°C / +113°F.

Humidity: relative humidity up to 99%.

F500 HIK:

Temperature -3°C to +45°C / +27°F to +113°F).

Humidity: relative humidity up to 99%.

Cooling time for an empty HIK cabinet to -3°C / +27°F is approx 30 minutes.

F500 HIF:

Temperature -18°C to +45°C / -0.4°F to +113°F.

Humidity: relative humidity up to 99%.

Cooling time for an empty HIF cabinet to -18°C / -0.4°F is approx 45 minutes.

Stainless steel or black

Choice of colors: Neutral stainless steel or black.

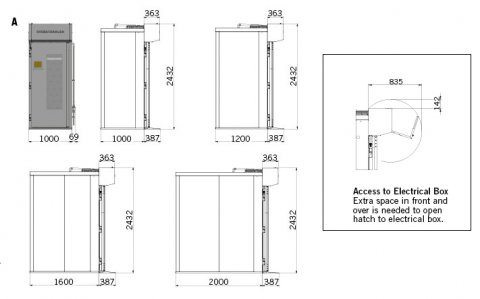

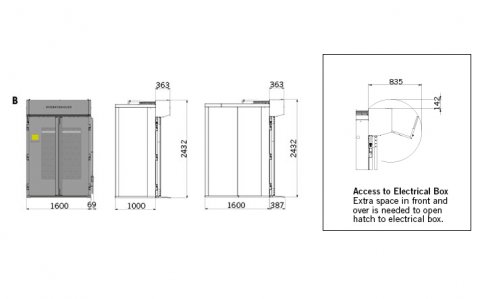

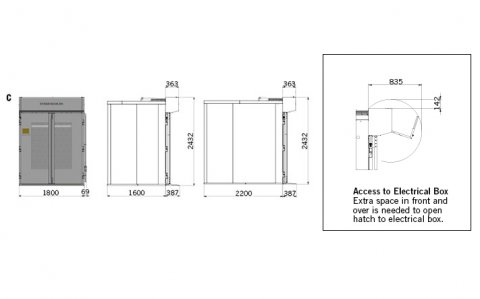

Sizes

F-Series F500 is available in eight sizes (width x depth):

1000x1000 mm, 1000x1200 mm, 1000x1600 mm, 1000x2000 mm.

1600x1000 mm, 1600x1600 mm.

1800x1600 mm, 1800x2200 mm.

Standard height not including insulated heated floor (not HIF): 2400 mm.

Height with insulated heated floor (standard for HIF): 2432 mm.

Key features

Control Panel

User-friendly touch panel that streamlines and simplifies the work in the bakery.

Demand Controlled Fans

Fan speed is controlled as needed to process the dough so just the right amount of air is circulating inside the cabinet.

Specially-designed air distribution channel

A specially-designed air distribution channel in the rear wall of the cabinet distributes the air very effectively.

HIF comes with Insulated Heated Floor

HIF (Freezer) comes with an insulated heated floor that counteracts freezing damage to the underlying floor and keeps it dry and free from condensation.

Easily monitored process

Large insulated windows with double glazing and vertical LED strips with daylight effect give the user a good overview of the proofing process on all the sheets in the rack trolley.

Robust insulated doors

Self-closing doors equipped with high quality hinges and ergonomic, rounded handles, as well as well-insulated double glazed tempered glass windows.

Specifications

Technical Specifications

| HIJ | Proofer for resting and proofing. |

| HIK | Retarder-proofer for retarding and proofing. |

| HIF | Freezer-proofer for freezing and proofing. |

| MODEL width x depth | Dough weight | No. Of fans | Fuse (amp) | Heating output HIJ/HIF/HIK |

Cooling output* HIK retarder-proofer |

Cooling output** HIF freezer-proofer |

| 1000 x 1000 mm (A) | 30 kg | 1 | 20A | 2 kW | 1.2 kW | 1.3 kW |

| 1000 x 1200 mm (A) | 30 kg | 1 | 20A | 2 kW | 1.2 kW | 1.3 kW |

| 1000 x 1600 mm (A) | 60 kg | 1 | 20A | 4 kW | 1.9 kW | 1.1 kW |

| 1000 x 2000 mm (A) | 90 kg | 1 | 20A | 4 kW | 1.9 kW | 1.1 kW |

| 1600 x 1000 mm (B) | 60 kg | 2 | 20A | 4 kW | 1.9 kW | 1.8 kW |

| 1600 x 1600 mm (B) | 120 kg | 2 | 20A | 6 kW | 3.2 kW | 2.1 kW |

| 1800 x 1600 mm (C) | 180 kg | 2 | 20A | 6 kW | 3.6 kW | 3.5 kW |

| 1800 x 2200 mm (C) | 180 kg | 3 | 25A | 8 kW | 4.0 kW | 4.3 kW |

The dough weight indic.ated refers to the quantity of dough the

cooling outputs of the freezer and retarder are calculated for (30 kg each).

The F500 with a width of 1000 mm has one door.

The F500 with either a width of 1600 or 1800 mm has two doors.

Compressor included. Delivered seperately.

Standard Refrigerant is R452.

Choice of steam cooker:

6 mm: Choose the 6 mm steam cooker when the water is really clean with few particles. The cleaner water the lower conductivity.

12 mm (Standard): Most times the 12 mm steam cooker is the best choice.

Round: Choose round when the water quality is low, with lots of particles in the water.

* Recommended output

** An insulated and heated floor is standard for the freezer-proofer.

Number of racks, max rack size.

| Model width and depth [MM] | 510 x 600 | 700 x 550 | 760 x 535 | 800 x 660 | 1040 x 760 |

| 1000 x 1000 | 1 | 1 | 1 | – | – |

| 1000 x 1200 | 1 | 1 | 1 | 1 | – |

| 1000 x 1600 | 2 | 2 | 2 | 1 | 1 |

| 1000 x 2000 | 3 | 3 | 3 | 2 | 1 |

| 1600 x 1000 | 2 | 2 | 2 | 1 | 1 |

| 1600 x 1600 | 4 | 4 | 3 | 2 | 1 |

| 1800 x 1600 | 6 | 4 | 4 | 2 | 2 |

| 1800 x 2200 | 9 | 6 | 6 | 4 | 3 |

Max. rack height: 1900 mm.

Height including insulated heated floor: 2432 mm.

Standard height not including insulated heated floor (not HIF): 2400 mm.

Total height when opening the hatch to electrical box:

With insulated heated floor: 2462 mm.

Without floor: 2430 mm.