BREAD LINE 180

The Glimek Bread Line 180 is designed for continuous dough processing and is a user-friendly, flexible and labor saving dough make up line, with high capacity and efficiency for smaller bakeries as well as medium size bakeries and larger bakeries. Also works as a pastry make-up line. The bread line, with a capacity of up to 1800 pieces/hour, handles a large variety of dough types and bread sizes. Make all from pastries to buns, baguettes and pizzas. See components set-up example below. All Glimek dough handling machines can be bought individually and are adaptable to several other brands on the market.

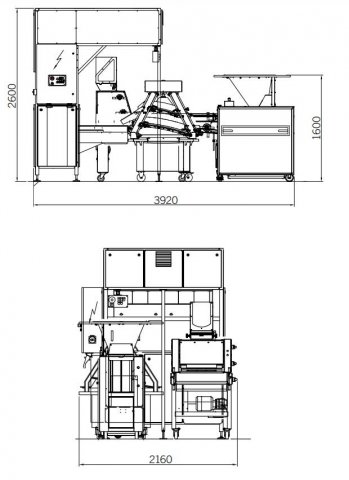

Bakery machines set-up example:

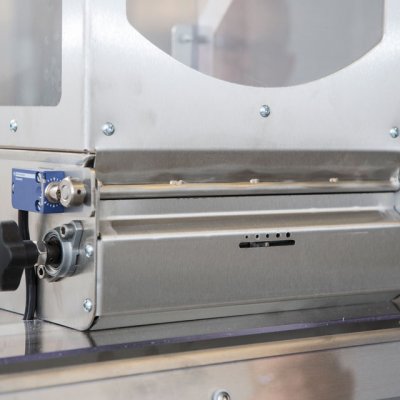

- SD180 Volumetric dough divider with weight range 120-1600 gr. Variable speed with frequency converter 750-1800 pcs/h, 90 liter stainless steel hopper, non-stick coated.

- CR400 with centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12h, outfeed chute and mechanical flour duster.

- IPP6/22 Intermediate Pocket Proofer with 132 effective pockets, single infeed V-belt conveyor L=750 mm. Photocell controlled, non-stick coated, infeed conveyor combined with continuous pocket proofer drive. Variable speed on the proofer. Electric control panel under projecting overhang, electric sockets for Divider, Rounder and Moulder. Max proving time 4,3 min at 1800 pcs/h.

- MO300 Bread moulder with centrally adjustable infeed in hopper, two pair of rollers, pressure board 650x1100 mm, collection tray.

Features

High capacity, up to 1800pcs/h.

Weight range 100-1500 gr.

For production down to 100 gr. Mini piston and adapter accessory is required.

Proofing time depending on capacity pieces/hour and size of intermediate proofer IPP.

Labour saving, consistent production.

Flexible bread line for a variety of doughs and bread types.

Key features

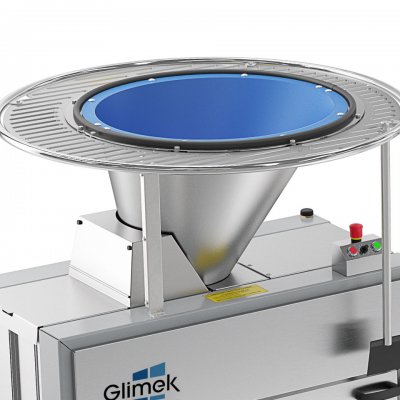

High safety

Highest safety with auto stop function. The safety ring makes it hard to reach down the hopper. The safety edge automatically stops the dough divider if it is exposed to pressure.

High dough weight accuracy

High dough weight accuracy, delivers desired weight for every dough piece.

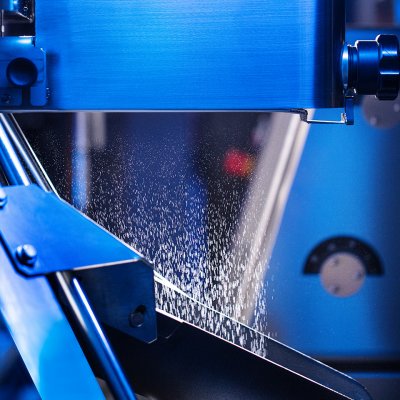

Flour Duster

Non-stick coating on cone

Non-stick coating on cone and tracks for ultimate rounding. Dough does not stick as well which makes it easy to clean.

Control Panel

User-friendly, movable control panel, easy to learn and to make adjustments.

Flexible and Modular design

Modular and flexible design. Can be expanded. Up to 1128 effective pockets as standard. Larger proofers on request.

UV-lighting

UV-lighting inside the IPP Intermdidate pocket proofer with on / off function.

Centrally adjustable infeed flaps

Centrally adjustable infeed flaps with size indicator, enables correct positioning of the dough pieces.

Parallel adjustable side guides

Parallel adjustable side guides in stainless steel for more efficient positioning of the dough pieces.

20 mm in food approved plastic or 10 mm with non-stick coating.

Flexible production

Flexible production with Moulder MO300, manages many different doughs, wide weight range: 30 - 1800 g. and can produce a wide range of end products.

Collection tray

Collection tray with two positions which catches the dough pieces after the moulding, enables straight line outfeed.

Common E-Stop

Common emergency stop - stop all bread line components with any emergency stop in the bread line.

Specifications

Technical Specifications

Capacity range: 750-1800 pcs/h

Weight range: 100-1500 gr

Fuse (amp): 16-25A

Power supply (Component example above) 6.38 kW