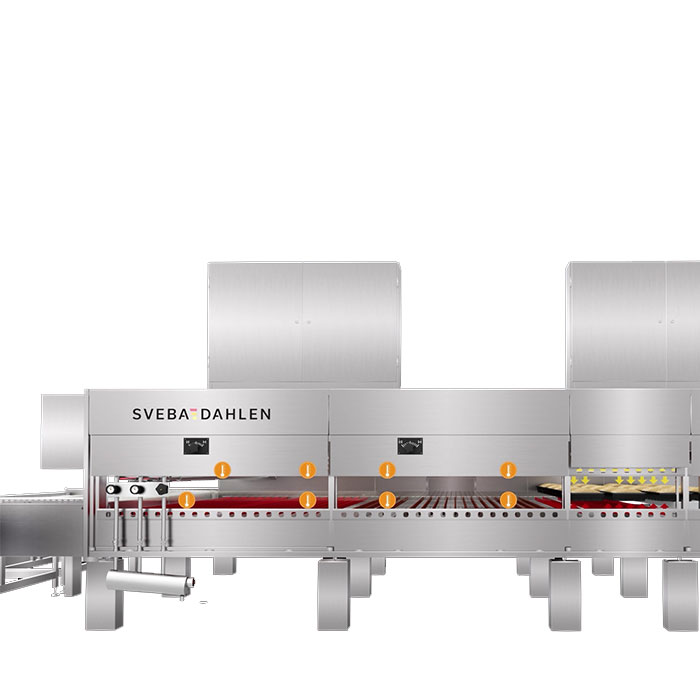

Fossil Free Electric Tunnel Oven

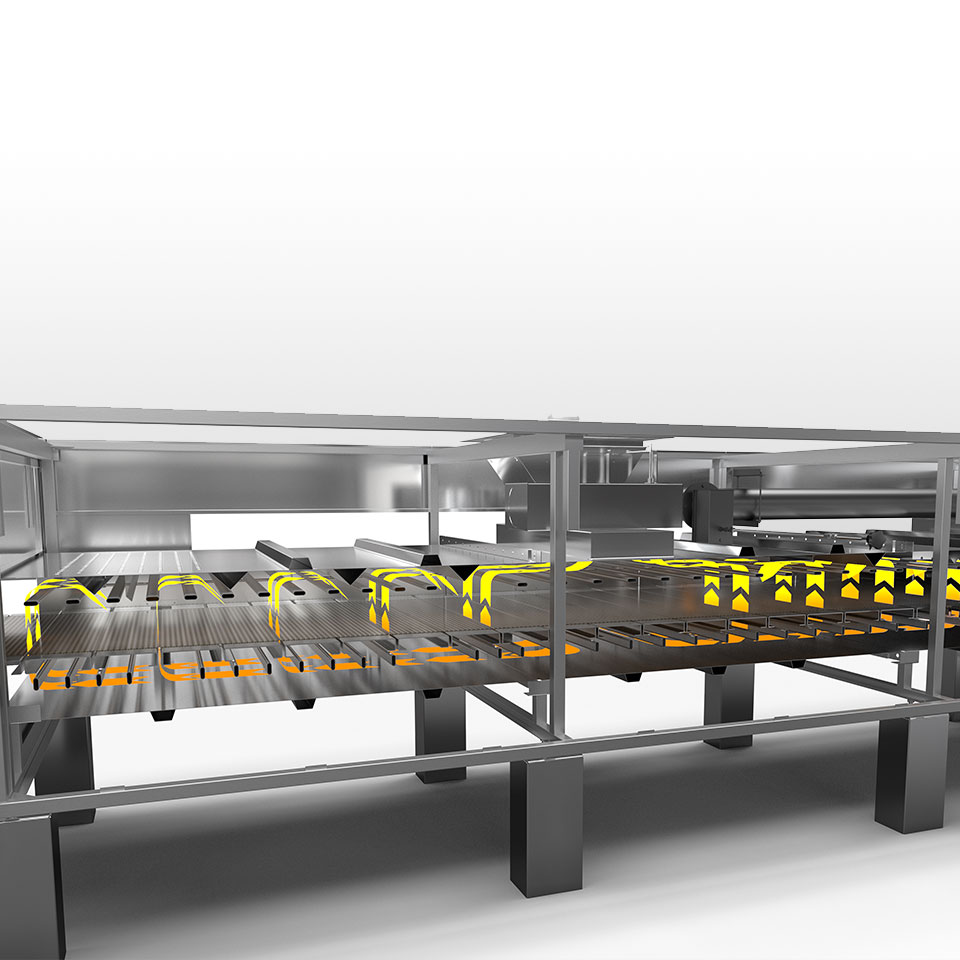

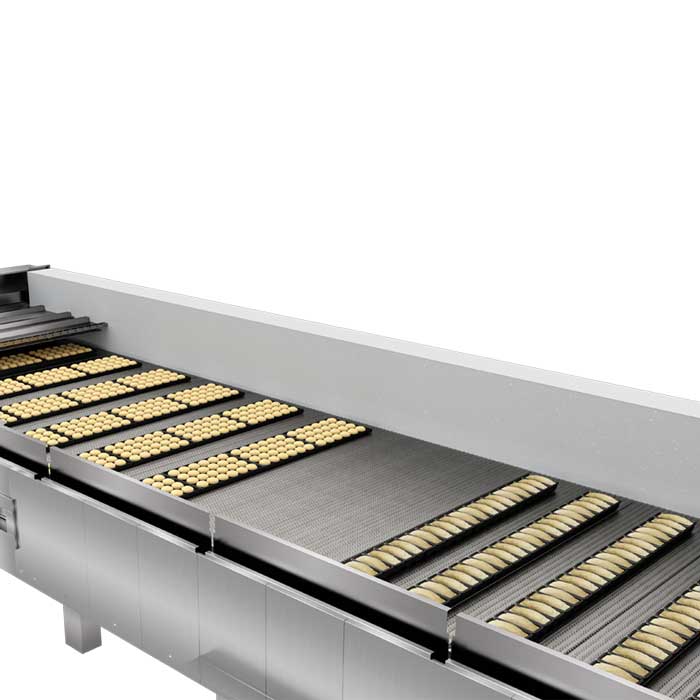

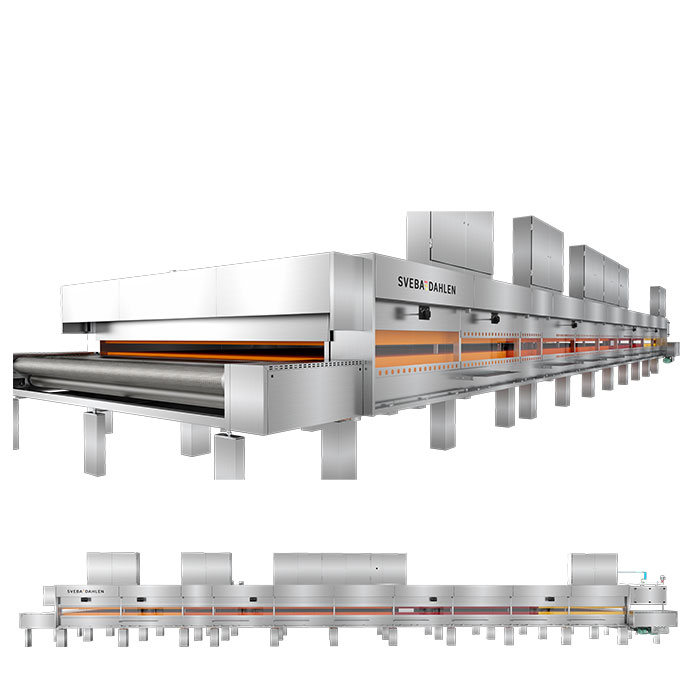

Sveba Dahlen delivers electric tunnel ovens to customers all around the world. Electric tunnel ovens used for continuous baking of all types of bread and pastry at temperature up to 500°C, 932°F. Sveba Dahlens electric heated tunnel ovens have been produced for more than 60 years with a proven record of reliable round the clock production. Each oven is based on a basic concept and then adapted to the customer’s wishes and requirements. The ovens can be equipped with many types of belts, such as different kinds of wire mesh belts and solid steel belts. Electric heated ovens are produced with belt widths up to 4,2 m. They are produced in two different basic models, depending on the baking temperature to be used. “Normal temperature ovens” of up to 350°C and “high temperature ovens” of up to 500ºC are available. The ovens are suitable for a variety of products, ranging from buns to bread, cakes, moon-cakes and pastries.

- “Normal” up to 350°C “High” temperature up to 500°C (932F).

- Available belt widths: 0,5 m to 4,2m (1,64 ft to 13,78 ft).

- All ovens are designed by requested capacity, available lengths 4 – 75 m (so far) (13,12 – 246 ft).

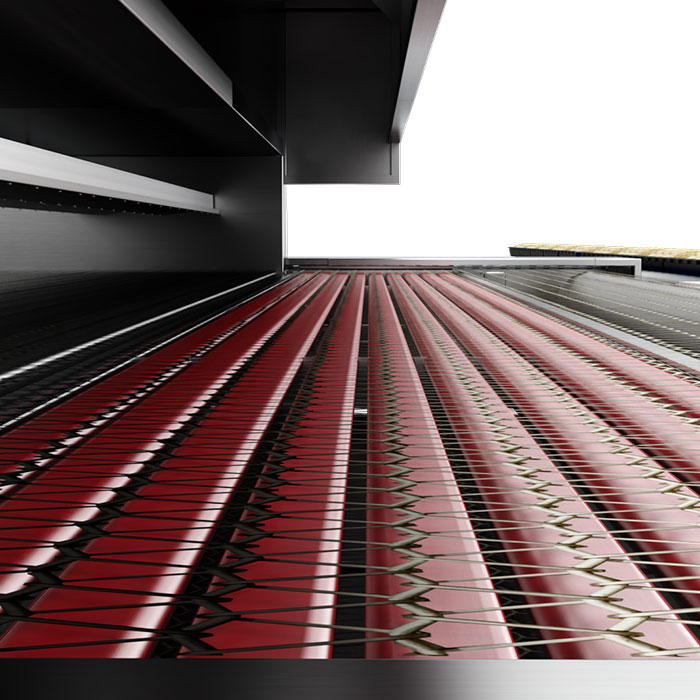

- Available belt types: Wire mesh belt and Solid steel belt.

Features and Benefits

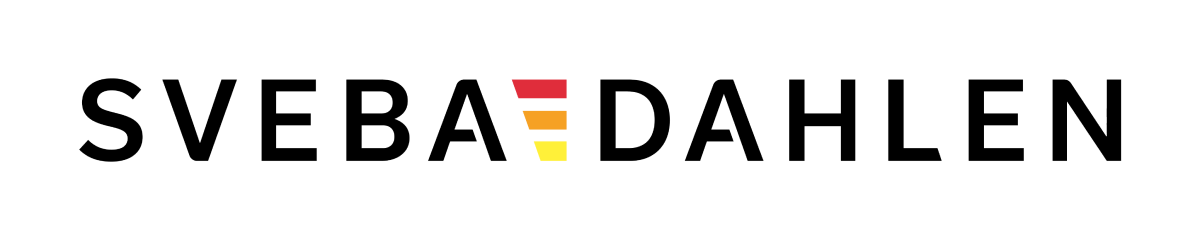

Heating

The tunnel ovens are heated by tube elements with double heating spirals. They are specially made for each oven to maximize the heat control and reliability of the elements. On average we use 12 elements per meter of oven. The elements, placed on the top of the oven chamber and below the belt, are easily accessed from the side.

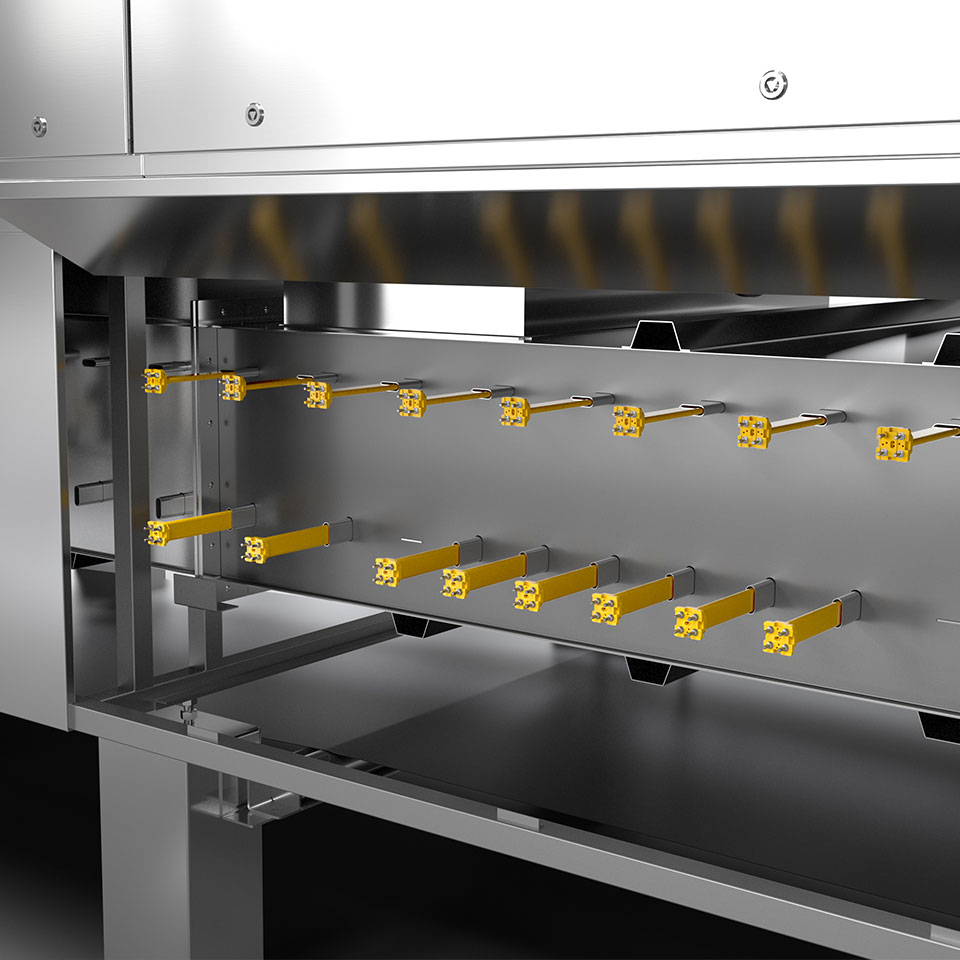

Turbo Zone with Vertical Airflow

For some products, especially when baking with tins, the use of air circulation from turbo fans in combination with radiant heat is suitable. In such cases the oven is equipped with turbo zones. In a mesh belt oven, the hot air is forced through the belt and allows for the baking time to be reduced, lower temperatures used and more equal colouring. With the adjustable fan speed the optimal turbo effect can be reached.

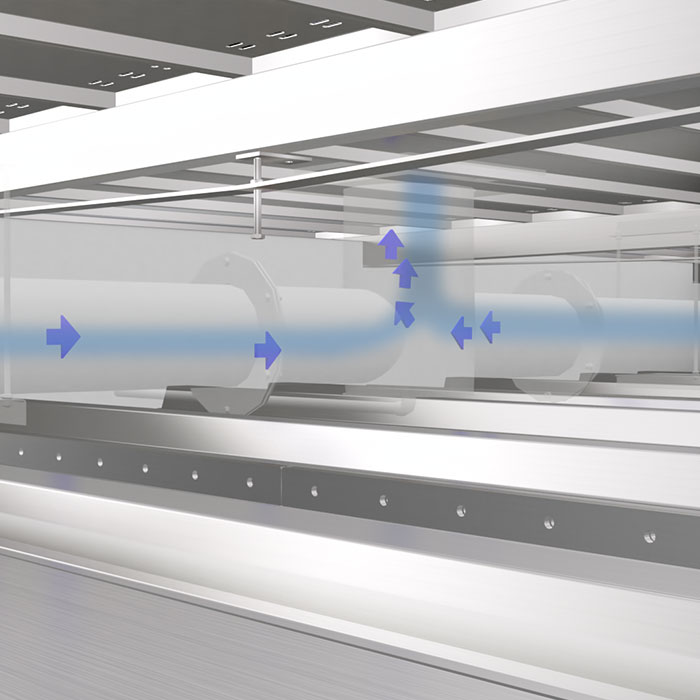

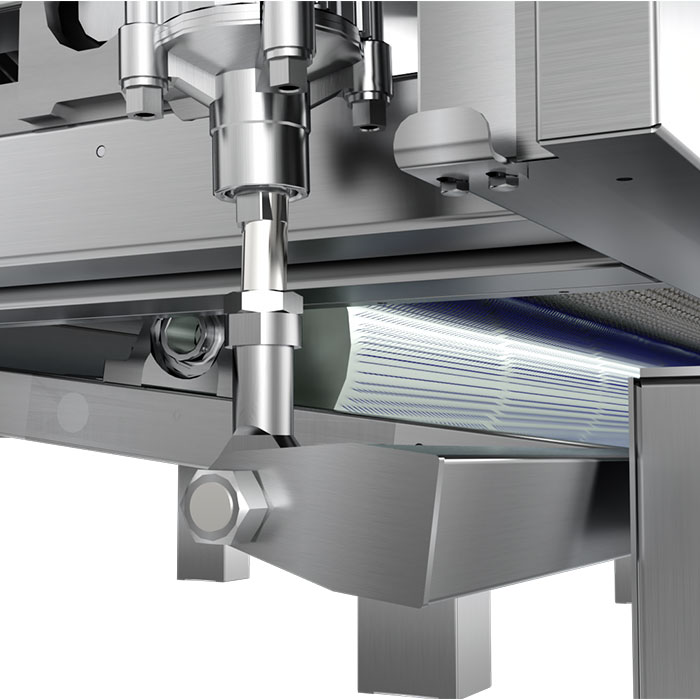

Turbo Zone with Horizontally Airflow

For some products, especially when baking with tins, the use of air circulation from turbo fans in combination with radiant heat is suitable. In such cases the oven is equipped with turbo zones. The horizontal airflow can be used with either mesh belt or a solid steel belt. This works because the hot air is blown horizontally along the zone. Turbo zones allows for the baking time to be reduced, lower temperatures used and more equal colouring. With the adjustable fan speed the optimal turbo effect can be reached.

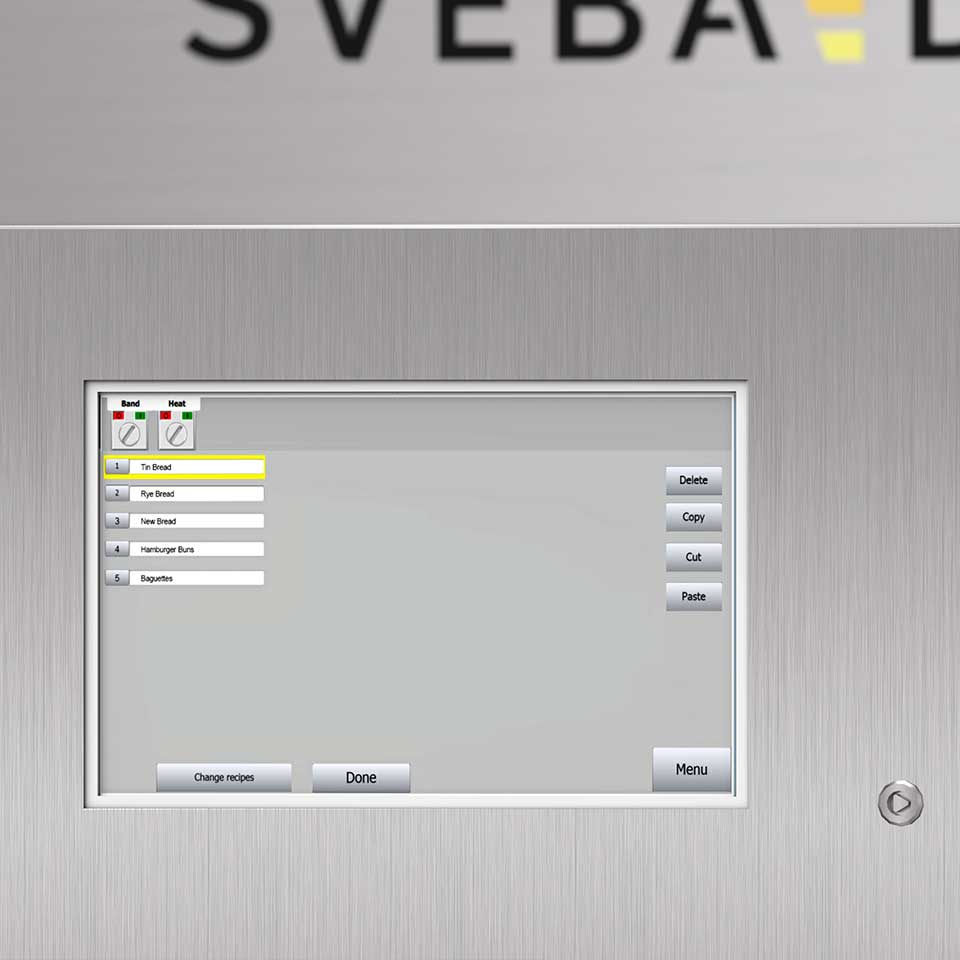

HMI Control Panel

The HMI control panel with touch screen is easy to overview and operate. Control the top and bottom heat in all zones, recipes, alarms and more. Get informative logs and do your software updates over the internet - quick and simple.

Q-Line Recipe Management for Tunnel Ovens

Continually switches recipes within a zone as soon as the zone is empty. Automatically adjusts settings such as temperatures, turbo, steam, humidity, and damper.

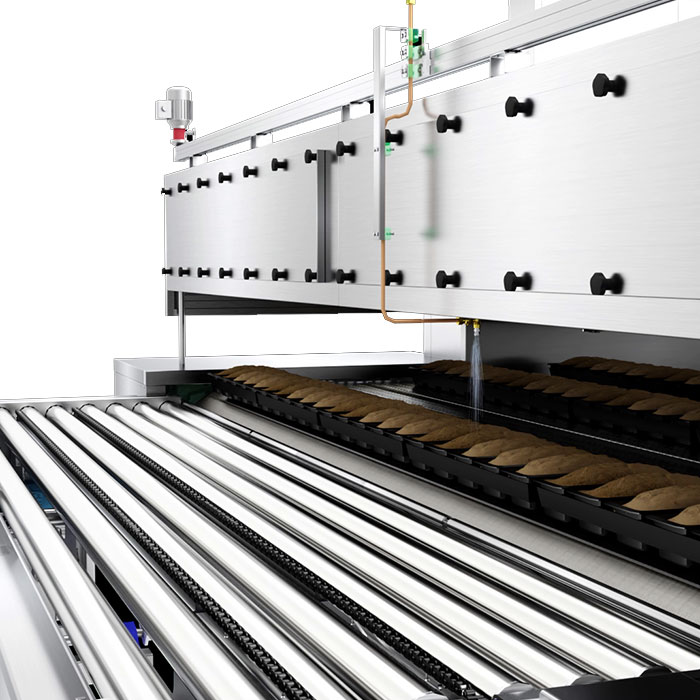

Steam with Photocell control

In ovens equipped with a steam system the first part of the oven contains steam spread boxes made out of the highest grade of stainless steel. Valves with indicators are used to adjust the proper flow of steam. Possibility to add photocell controlled and/or volume of steam/h system. With a photocell controlled steam system, the steam is activated when the photocell detects a product. The steam then turns off after a preset delay when there are no more products to process. The steam amount can be finely adjusted digitally or mechanically.

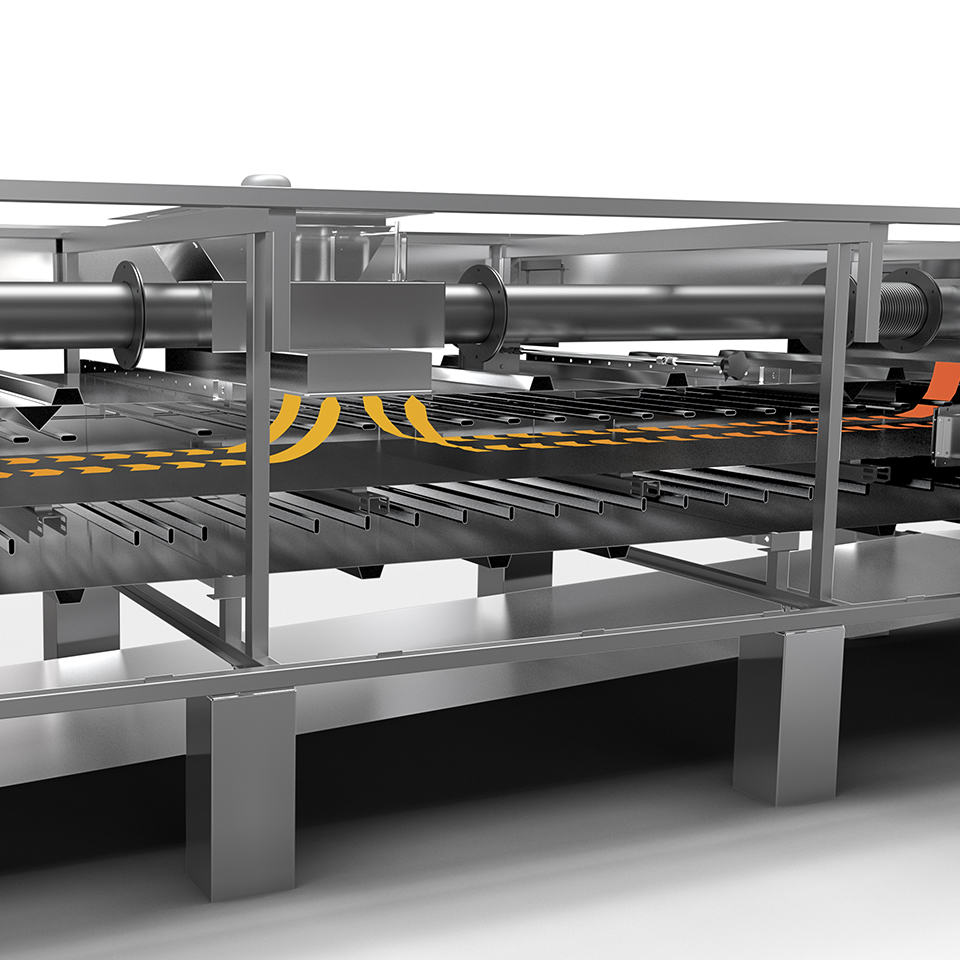

Belt driving system

A frequency converter controls the speed of the drive motor, and the robust belt driving system provides optimal reliability and exact baking time. Long ovens and ovens for heavy products are fitted with double drive system, each with its own motor.

Inspection door

The windows have inspection doors made of glass, with built in lighting for easy supervision of the baking process (not with high temperature version). Exhaust damper manually adjustable or, as an option, motor-driven together with PLC control.

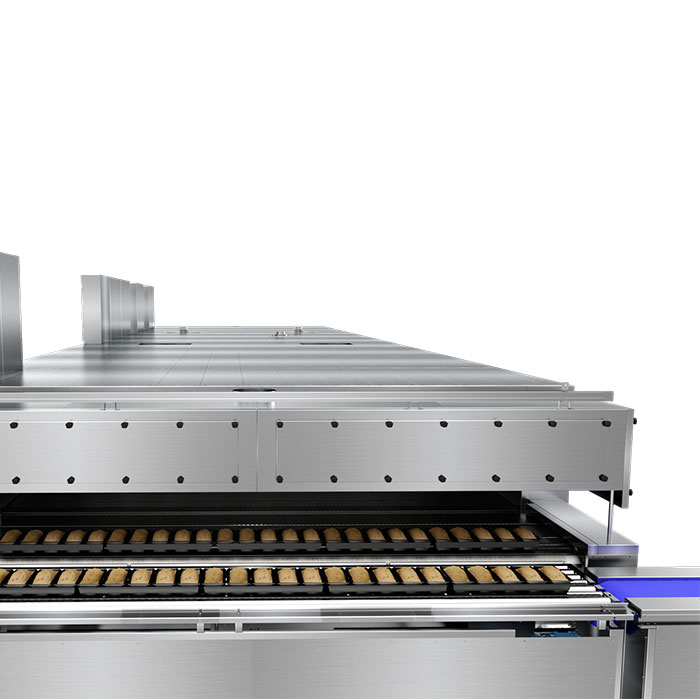

Tunnel Oven Mesh Band

Tight wire mesh belt for free standing bread.

Tunnel Oven Mesh Band

Open wire mesh belt for tin breads and trays

Solid steel belt

Solid steel belts for dough and bread directly on the belt or in tin cans.

Can only be used with electrial tunnel ovens.

Energy Saving Technology

Sveba Dahlen tunnel ovens are built with super insulating material that ensures that very limited heat escapes from the ovens resulting in the exterior being relatively cool. The exterior is made of stainless steel and our ovens are known throughout the world for their advanced technology and energy efficiency.

Heating Zones

Individually adjustable heating zones, with separate control of top and bottom heat. These efficient ceramic heating elements are only used when and where they are needed.

Pre-heater

Variable pre-heater controlled from the control panel. Heats up the oven belt before it enters the oven.

Belt tracker

Sensors continuously monitor the movement of the oven belt and adjust it automatically if deviations are detected.

Temperature Sensors

Temperature Sensors both high and low in each heating zone. Ensuring precise temperature control.

Damper Function

Manual or digital damper function with mechanical doors or sensor-controlled doors. Parameters are adjusted according to recipe settings on the HMI control panel. Sensors in the different zones gives control of the humidity level.

Water spray

Water spray at the output improves the surface and crust of the bread, enhancing its esthetic quality.

Infeed Conveyor and Loader

Customized to suit the production needs. Adjustable speed can be linked to the oven's control panel. A hydraulic air cylinder pushes products onto the oven belt.

Outfeed Conveyor and Unloader

Outfeed conveyor and unloader can be customized to suit your needs. Adjustable speed and control of settings can be integrated with the oven's control panel.

Belt Brush

Rotating belt brush with pneumatic lifting device efficiently cleans the underside of the oven belt.

High-Temperature Baking

Sveba Dahlen's tunnel ovens offer standard temperatures up to 320°C / 608°F, or high-temperature ovens with temperatures reaching up to 500°C / 932°F.

Options

All Tunnel Ovens are customer adapted, to fit the end product needs. Below is some of the options available.

Continuous recipe change.

Changing recipe continuously in a zone immediately when the zone is empty. Changing recipe baking time immediately when oven is empty. Available with automatic function and manual handling.

Steam Regulation.

Steam regulation on /off by photocell, off delay when no indicated bread.

Steam regulation on /off like above plus adjusting kg steam / hour.

Humidity measurement.

By using humidity sensors in the different zones the humidity parameter can be measured and controlled.

Rotating belt brush.

Pneumatically, liftable and rotating brush for regularly cleaning.

Motorized dampers and oven doors.

Recipe controlled damper and oven door positions.

Thyristor controlled heat.

For a more accurate regulation, the heating elements can be controlled by thyristor regulation.

Water spray at the outfeed.

Gives a shinier product and improves the crust.

Walkway on top of the oven.

Simplifies cleaning and service.

Frequency inverters for the oven chamber exhaust fan(s).

Adjust the fan speed from the PLC screen. The system can be expanded for continuous under pressure / flow regulation.

Air Flow Turbo Zone.

Frequency controlled speed. Individual setting for different recipes. Top heat turbo with air flow above the belt and/or with vertically Turbo air flow through the belt.

Frequency controlled fan speed.

Individual setting for different recipes.

High power section in zone 1.

Add extra power heat elements in the first part of the bottom heat chamber. Controlled from PLC screen, and specified in the recipes.

kWH-meter including heating element status check.

In each zone box there are current transformers on the main cable after the main switch.