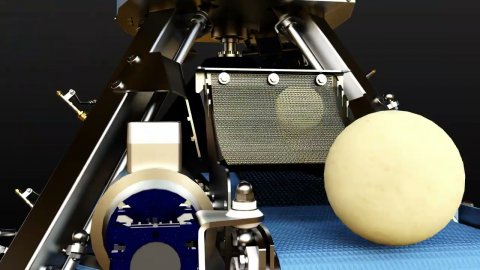

Conical Dough Rounder - CR600

A very flexible and high capacity conical rounder for all kind of bakeries, suitable for most types of dough. Capacity up to 6000 pieces per hour and weight range between 30 and 1800 grams. The cone and tracks has non-stick coating which makes it easy to keep clean.The conical rounder has two individually adjustable rounding sections that processes the dough for ultimate rounding and optimized result. The cone rounder can be equipped with a wide range of utilities to fit most productions, mechanical flour duster, hot- and cold air blowing unit, variable cone speed, oiling of cone and outfeed conveyor. Perfect rounding of dough with Glimek conical rounder CR600.

Flexible Dough Weight

Long Rounding Length

Movable

High Capacity

Features

Capacity up to 6000 pcs/h subject to dough piece weight and characteristics.

Weight range 30-1800 g, subject to capacity and dough characteristics.

Wide variety of options make it possible to meet the customer demand.

Flexible setup.

Flexible regarding type of dough.

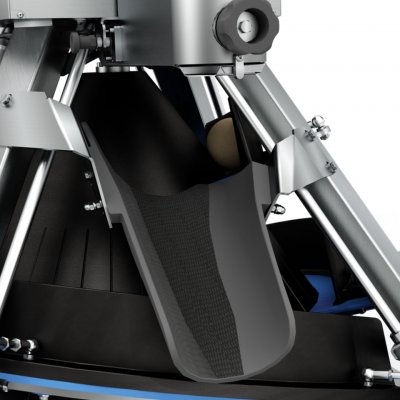

Special designed infeed track catches the dough in a smooth and gently way, manually adjusted.

Individual adjustable settings for rounding tracks and merging tracks:

- Centrally adjustable rounding tracks (conical part).

- Manually adjustable merger tracks (cylindrical part).

Long rounding length, up to 8 m depending on infeed position.

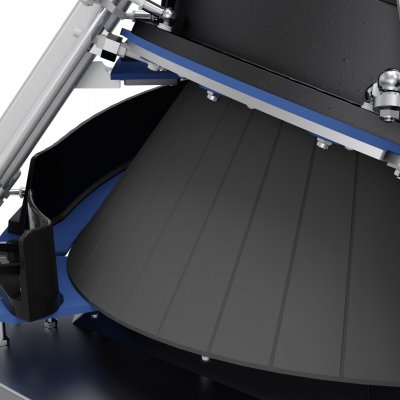

Non-stick coating on cone and tracks for ultimate rounding.

Cone with grooves for optimized grip.

Hygienic materials, easy to clean due to adjustable tracks and stainless steel execution.

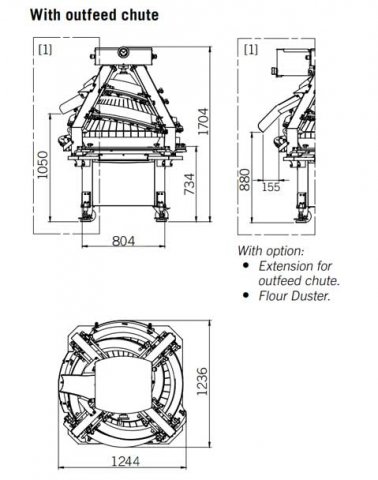

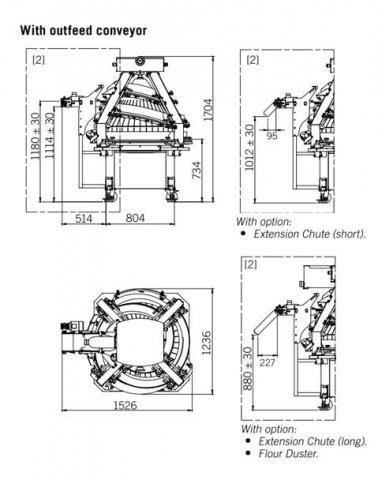

Outfeed chute with small dimples for better outfeed properties.

Flexible layout with possible infeed track at 3, 6 or 9 o'clock.

Operation panel easily accessible from both sides.

Handle on left or right hand side.

Stainless steel frame and cover.

Robust construction with strong frame, steady support feet and high quality premium castors.

Stainless steel castors with bearings and blue plastic.

Blue plastic track bottom plate.

Blue plastic parts for better detection and food safety.

Cable suspension underneath facilitates cleaning.

High safety with two emergency stops with easy access from both sides

Easy to install.

INFEED ALTERNATIVES

Outfeed always at 12 o'clock.

Standard infeed at 6 o'clock.

Optional infeed at 3 or 9 o'clock.

Key features

Infeed track

Special designed infeed track, manually adjustable. Catches the dough in a smooth and gentle way.

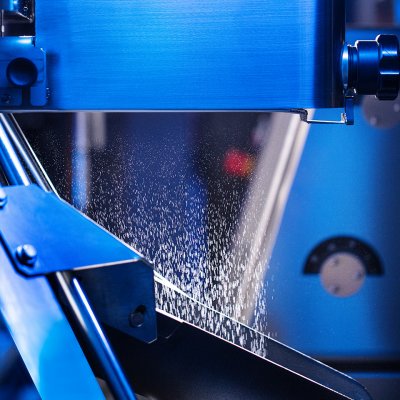

Flour Duster

Non-stick coating on cone

Non-stick coating on cone and tracks for ultimate rounding. Dough does not stick as well which makes it easy to clean.

Operation panel

User-friendly operation panel. Easy accessible from both sides of machine, wheel for adjustment of tracks can be placed either on left or right side.

Specifications

Technical Specifications

| Technical Details | |

| Capacity Subject to dough piece weight and characteristics |

Up to 6000 pieces/hour. |

| Weight Range (subject to dough piece weight and characteristics) |

30 - 1800 g |

| Fuse (amp) | 16A |

| Power Supply | 1.5 kW (3.8 kW with hot and cold air blowing unit) |