INTERMEDIATE POCKET PROOFER - IPP

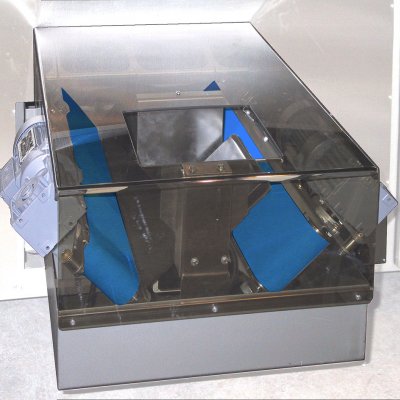

The Glimek Intermediate Pocket Proofer IPP is one of the most flexible pocket proofers on the market. With the IPP it is easy to adjust the dough resting time to fit the needs. It is made for 6, 8, 10 or 12 pockets and modulated for easy adaption in height and width for easy installation in most facilities and according to customer needs. It has a weight range between 100 and 1500 grams and a 2 different infeed system capacities; up to 1800 or 3000 pieces/hour. Available in standard models from 132 up to 1128 effective pockets, larger proofers can be made on request. It is working very quietly and the encapsulated design prevents skin from forming on the dough. The solid construction in stainless steel materials gives it a longer lifetime and makes it easy to clean.

Features

Models with 6-, 8-, 10-, or 12-pockets swings.

Modular system for up to 1128 pockets net as standard.

Stainless steel execution - easy to keep clean.

Flexible layout - choice of infeed position.

Weight range 100-1500 grams.

2 different infeed system capacity up to 1800 or 3000 pcs/hour.

Encapsulated design - prevents skin forming on the dough.

Non-stick coated transfer box.

Overfill Detection System (option).

Photocell System that reduces the need for monitoring the bread line. The Photocell System detects any larger dough spillage in the upper cabinet overhang and automatically stops the IPP for cleaning in time before large accumulations of dough are created.

Motor drive directly on shaft (no chains or timing belts).

Operation panel easy accessible under projecting overhang.

Electrical cabinet at working height with power supply and sockets for divider, rounder and moulder.

Blue plastic parts for better detection and food security.

Key features

UV-lighting

UV-lighting inside the IPP Intermdidate pocket proofer with on / off function.

Common E-Stop

Common emergency stop - stop all bread line components with any emergency stop in the bread line.

Flexible and Modular design

Modular and flexible design. Can be expanded. Up to 1128 effective pockets as standard. Larger proofers on request.

Control Panel

User-friendly, movable control panel, easy to learn and to make adjustments.

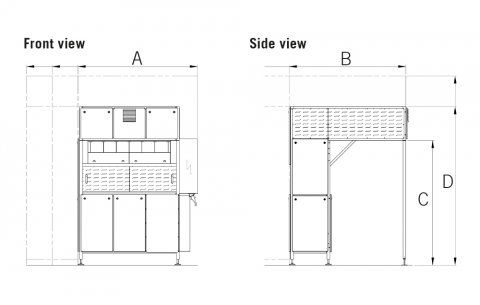

Specifications

Technical Specifications

Capacity range: up to 1800 or 3000 pcs/hour

Weight range: 100-1500 grams

Fuse only IPP (amp): 16A

Total fuse depending on connected make-up machines: 16-25A.

Power supply

(depending on connected make-up machines): 5.95-8.63 kW

Air supply (double infeed): 6 bar

| Max capacity, pieces/hour | 1800 (1) | 1800 (1) | 3000 (2) | 3000 (2) |

| No. of pockets in each swing/number of effective swings* |

Effective pockets | Proofing time at 1800 pcs/h | Effective pockets | Proofing time at 3000 pcs/h |

| Low Proofers H = 2600 mm** | ||||

| 6/2220 | 132 | 4.3 | - | - |

| 8/22 | 176 | 5.7 | 176 | 3.4 |

| 10/22 | 220 | 7.1 | 220 | 4.3 |

| 12/22 | 264 | 8.5 | 264 | 5.1 |

| 6/40 | 240 | 7.8 | - | - |

| 8/40 | 320 | 10.3 | 320 | 6.2 |

| 10/40 | 400 | 12.9 | 400 | 7.8 |

| 12/40 | 480 | 15.5 | 480 | 9.3 |

| 6/60 | 360 | 11.6 | - | - |

| 8/60 | 480 | 15.5 | 480 | 9.3 |

| 10/60 | 600 | 19.4 | 600 | 11.6 |

| 12/60 | 720 | 23.3 | 720 | 14.0 |

| 6/78 | 468 | 15.1 | - | - |

| 8/78 | 624 | 20.2 | 624 | 12.1 |

| 10/78 | 780 | 25.2 | 780 | 15.1 |

| 12/78 | 936 | 30.3 | 936 | 18.2 |

| High Proofers H = 3100 mm | ||||

| 6/26 | 156 | 5.0 | - | - |

| 8/26 | 208 | 6.7 | 208 | 4.0 |

| 10/26 | 260 | 8.4 | 260 | 5.0 |

| 12/26 | 312 | 10.1 | 312 | 6.1 |

| 6/48 | 288 | 9.3 | - | - |

| 8/48 | 384 | 12.4 | 384 | 7.4 |

| 10/48 | 480 | 15.5 | 480 | 9.3 |

| 12/48 | 576 | 18.6 | 576 | 11.2 |

| 6/72 | 432 | 14.0 | - | - |

| 8/72 | 576 | 18.6 | 576 | 11.2 |

| 10/72 | 720 | 23.3 | 720 | 14.0 |

| 12/72 | 864 | 27.9 | 864 | 16.8 |

| 6/94 | 564 | 18.2 | - | - |

| 8/94 | 752 | 24.3 | 752 | 14.6 |

| 10/94 | 940 | 30.4 | 94 | 18.2 |

| 12/94 | 1128 | 36.5 | 1128 | 21.9 |

*Total number of swings is always 4 more than effective number of swings.

**Not recommended in combination with the MO881 Moulder.

(1) IPP with single infeed V-belt conveyor L=750mm. Photocell controlled, non-stick coated, infeed conveyor combined with continuous pocket proofer drive. Variable speed on the proofer. Control panel under a projecting overhang, power supplies for the divider, rounder and moulder.

(2) IPP with dual infeed conveyor L=750 mm, centrally placed, photocell controlled, non-stick coated infeed V-belt conveyors. Flap system guides the dough pieces after the rounder. Compressed air is required, 6 bar. Variable speed on the proofer. Control panel under a projecting overhang, power supplies for the divider, rounder and moulder, and the outfeed cross conveyor.