Suction Dough Divider - SD600

The Glimek SD600 is a stainless multi pocket suction dough divider in 3-pocket or 2/4-pocket execution with reliable dividing system for very high weight accuracy. It has stepless adjustable dough pressure, which can be adjustable while running for very gentle handling of different types of dough. It has robust chassis, perfect for high industrial bakery production. Handles weight range between 150-1700 grams and has a capacity between 1000 and 6000 pieces per hour. The SD600 is a quality bread dough divider with high flexibility and high capacity, perfect for industrial and commercial bakeries, available with 100 liter or 225 liter hopper. Can be adjusted during operation.

Why you should have a volumetric Dough Divider from Glimek

The dough dividers from Glimek are volumetric. This means that the dough is pulled down into the hopper by suction where it gets cut off at the correct volume of the dough depending on the setting. With this technique, it is possible for the dough to have different fermentation times and still get perfect baking result since the pressure on the cut off dough is adapted after the fermentation process. This process gives an airier crumb and no, or very few, chemicals need to be added to the dough. When baking artisan, and more sensitive bread, the volumetric method is preferred since the volume development is much better compared to other methods.

High Weight Accuracy

Control Panel

Energy Efficient

High Capacity

Easy to Clean

Features

Measures the dough instead of weighing – dough weight will be consisent even if the dough starts to ferment in the hopper.

Weight range, two versions: 150-1000 gr as 3-pocket and 250-1700/100-700 gr as 2/4-pocket.

Capacity 1500-4500 pcs/h as 3-pocket, 2000-6000 pcs/h as 4-pocket and 1000-3000 pcs/h as 2-pocket (the measuring pistons are easily connected two and two).

All panels are easily opened (without tools) so cleaning the machine is made easy - including separated compartments for electrical access and oiling.

Variable speed with frequency converter.

Stepless adjustable dough pressure on pistons. Adjustable while running.

Very user friendly 8” touch screen for settings and storing recipes.

Stepless adjustable pneumatic system (compressed air required, min 6 bar) for very gentle handling of different types of dough. Can be adjusted during operation.

Reliable dividing system for very high weight accuracy.

Separate drive on outfeed belts.

Smart monitored lubrication systems to get long life out of the machine.

Quick release on outfeed conveyor.

High attention on both safety and hygienic aspects in the development.

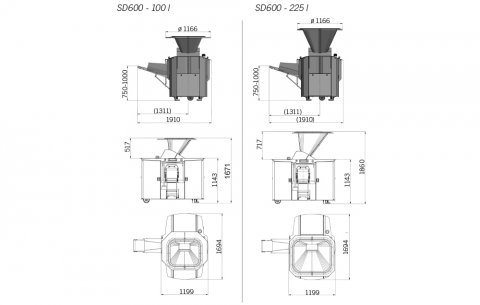

100 liter stainless steel hopper as standard (~70 kg dough).

225 liter stainless steel hopper (~150 kg dough) (option).

Non-stick coated hopper (option).

Compressed air is required.

Equipped with a patented gas spring system that allows relative motion between the motor and the dough feeding plunger, so that the pressure applied on the dough can be controlled. The working pressure on the gas spring can easily

Parts in blue for better detection and food safety.

Key features

Continuous production

The SD600 Dough Divider is a high quality and robust piece of machinery. Strong materials and smart lubrication systems to get long life out of the machine.

Powerful Touch Panel

High dough weight accuracy

High dough weight accuracy, delivers desired weight for every dough piece.

Flexible regarding type of dough

Equipped with a stepless adjustable pneumatic system (compressed air required, min. 6 bar) for very gentle handling of different types of dough. Can be adjusted during operation.

Specifications

Technical Specifications

Capacity range

3-pocket: 1500-4500 dough pcs/h

2/4-pocket: 1000-3000/2000-6000 dough pcs/h

Weight range, subject to capacity and dough characteristics:

3-pocket: 150 - 1000 gr

2/4-pocket: 250-1700/100 - 700 gr

Fuse (amp): 25A

Power supply: 3.5 kW

Compressed air (Required): 6 bar