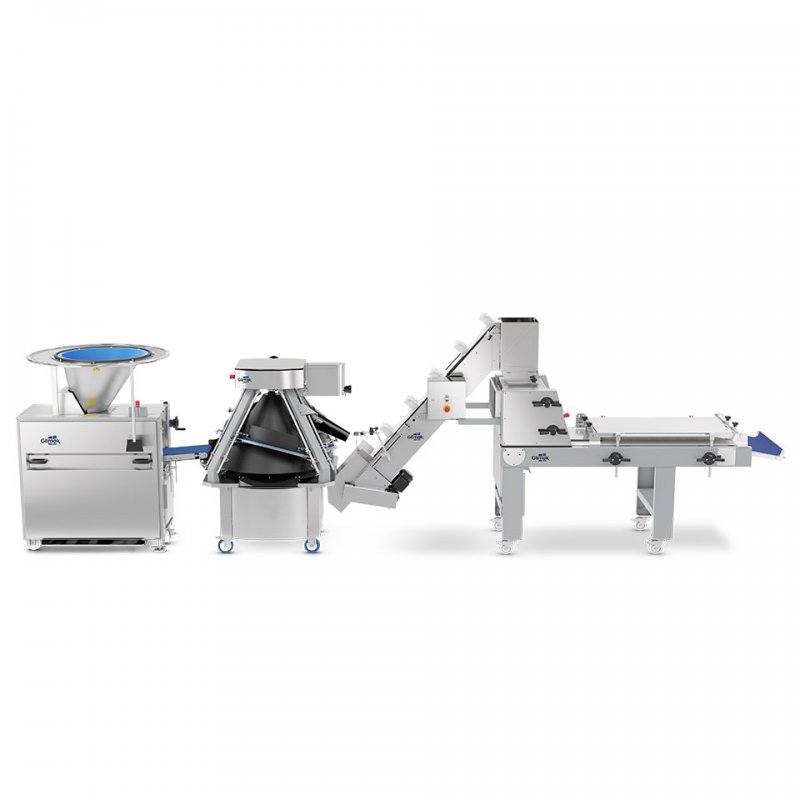

Bread Line 180 Direct

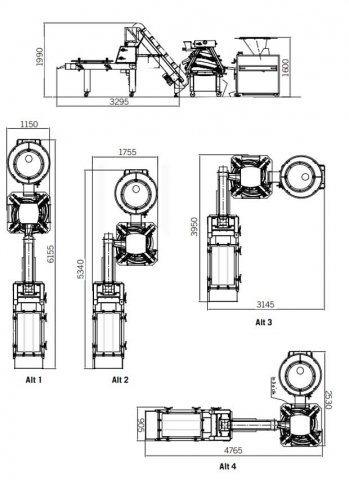

The Glimek Bread Line 180 Direct is specially made for producing bread without need for an intermediate proving time. It's a very compact breadline with a high capacity - up to 1800 pieces/hour. The weight range is 120–1600 g. Bread Line 180 Direct is a labour saving, time saving and space saving breadline for a flexible and consistent production in the bakery. This bread line is perfect for industrial baking and commercial bakeries with higher volumes. See components setup example below. All machines in the dough make-up line can be bought separately.

Bakery machines set-up example:

-

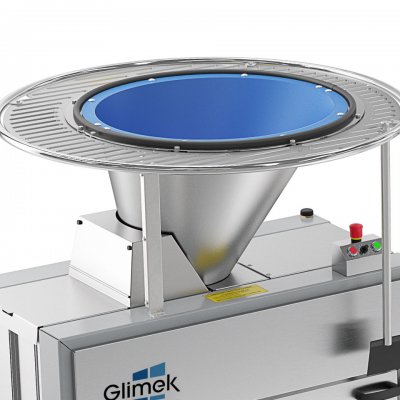

SD180 Dough Divider, Volumetric dough divider, weight range 120-1600 gr, variable speed with frequency converter 750-1800 pcs/h, 90 liter stainless steel hopper, non-stick coated.

-

CR400 Conical Rounder, with centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12h, oufeed chute and mechanical flour duster.

-

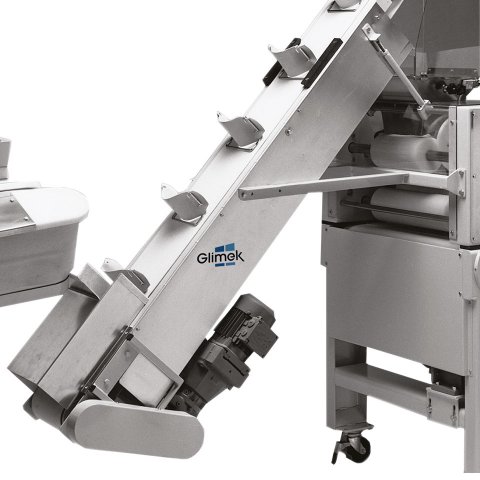

CE100 Cup Elevator, mounted on moulder MO300, photocell controlled, working step by step to link up cone rounder with Moulder, including electrical cabinet mounted on elevator. Capacity 50-1000 gr.

-

MO300 Moulder, with centrally adjustable infeed in hopper, two pair of rollers, pressure board 650x1100 mm, collection tray.

Features

Specially made for producing breads without an intermediate proving time.

Very compact bread line with a high capacity - 1800 pcs/h.

Flexible breadline which handles a variety of doughs.

Labour, time and space saving bread line.

Flexible and consistent production.

Key features

High safety

Highest safety with auto stop function. The safety ring makes it hard to reach down the hopper. The safety edge automatically stops the dough divider if it is exposed to pressure.

High dough weight accuracy

High dough weight accuracy, delivers desired weight for every dough piece.

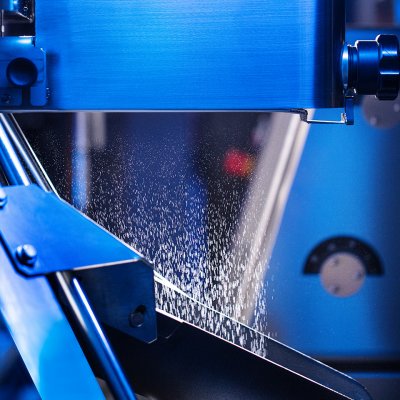

Flour Duster

Non-stick coating on cone

Non-stick coating on cone and tracks for ultimate rounding. Dough does not stick as well which makes it easy to clean.

Feeding system

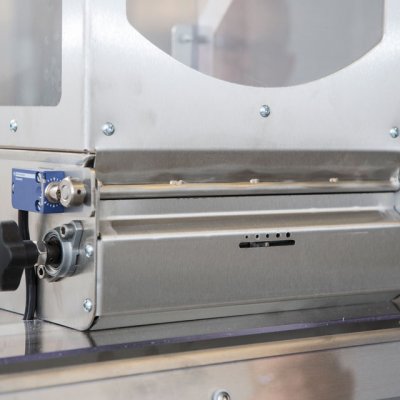

Photocell controlled feeding system. The timing of each dough piece is controlled by a photocell.

Stainless steel execution

Stainless steel execution makes it easy to clean and long service life.

Centrally adjustable infeed flaps

Centrally adjustable infeed flaps with size indicator, enables correct positioning of the dough pieces.

Parallel adjustable side guides

Parallel adjustable side guides in stainless steel for more efficient positioning of the dough pieces.

20 mm in food approved plastic or 10 mm with non-stick coating.

Collection tray

Collection tray with two positions which catches the dough pieces after the moulding, enables straight line outfeed.

Flexible production

Flexible production with Moulder MO300, manages many different doughs, wide weight range: 30 - 1800 g. and can produce a wide range of end products.

Specifications

Technical Specifications

Capacity range: Up to 1800 pcs/h.

Weight range: 120-1600 gr.

Fuse (amp): 18A

Power supply (Component example above): 3.95 kW.