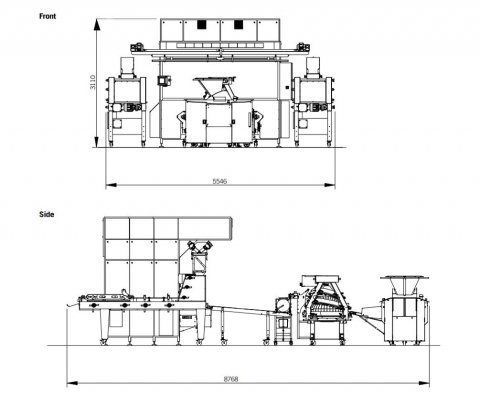

BREAD LINE 450

The Glimek Bread Line 450 includes robust dough handling machines designed for consistent and continuous production around the clock. The Glimek baking machines are made of high quality materials, mostly stainless steel, that ensures excellent dough results and in the end best baking results. This powerful industrial bread line has a capacity of up to 4500 pieces/hour, a dough weight range between 100 and 1500 grams and an adaptable proofing time.

The Glimek bread line is labor saving, energy efficient and user-friendly as well as safe due to the integrated emergency stop.Turn into a dough handling bakery easily with heavy-duty bakery machinery, made in high quality components, that carefully handles the dough for perfect baking results!

Features

Dough handling equipment set-up example (all pieces can be bought separately):

Suction Dough Divider - SD600

A stainless, multi pocket, volumetric, dough divider in 3-pocket or 2/4-pocket execution. Stepless adjustable dough pressure, adjustable while running. Robust chassis for high industrial bakery production.

• Weight range, two versions: 150-1000 g as 3-pocket and 250-1700 / 100-700 g as 2/4-pocket.

• Capacity 1500-4500 pcs/h as 3-pocket, 2000-6000 pcs/h as 4-pocket and 1000-3000 pcs/h as 2-

pocket (the measuring pistons are easily connected two and two).

Conical Rounder - CR600

A very flexible cone rounder for all kind of bakeries, suitable for most types of dough. Two individually adjustable ball rounding sections processes the dough for ultimate rounding and an optimal result.

• Wide weight range 30 – 1500 g.

• Flexible regarding type of dough.

• Capacity up to 6000 pcs/h.

• Hygienic solutions, easy to clean due to adjustable tracks and stainless steel.

Dough Piece Separator - DPS

The DPS Dough Piece Separator, divides the line into two lines to increase the capacity of the breadline. Easy to install and to move.

• Required for increased capacity, up to 4500 pcs/hour.

• Hygienic belt and materials, easy to clean.

Belt Conveyor - BC250

The BC250 Belt Conveyor, transports the dough from the Dough Piece Seperator to the Intermediate Pocket Proofer. Easy to move and clean.

• Gives an opportunity for a final visual review of the dough.

• Hygienic belt and materials, easy to clean.

Intermediate Pocket Proofer - IPP1272

One of the most flexible Pocket Proofers on the market. For 6, 8, 10 or 12 pockets. Modulated for easy adaption in height and depth, available in standard models from 132 up to 1128 effective pockets. Solid construction in stainless steel materials.

• Stainless steel execution - easy to keep clean.

• Flexible layout - choice of infeed position.

• Weight range 100-1500 g.

• 4 different infeed systems. Capacity 4500 pieces/hour.

• Modular layout, enlarge the IPP if longer resting time is needed.

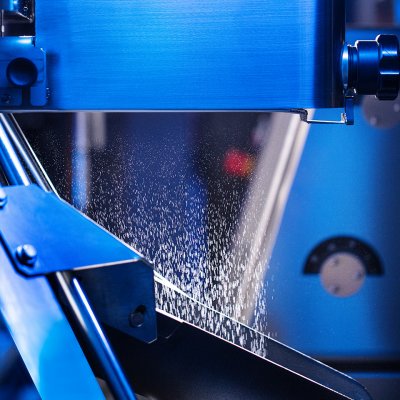

Bread moulder - MO881

The MO881 Moulder, is a robust, heavy duty, moulder for industrial bakeries. Triple moulding head, curling net and double pressure boards.

• Easy to operate.

• Easy to set up for perfect final moulding result.

• Dual pressure boards enables industrial production.

• Capacity up to 3600 pcs/h.

• Weight range 30-1800 g.

Key features

Flexible regarding type of dough

Equipped with a stepless adjustable pneumatic system (compressed air required, min. 6 bar) for very gentle handling of different types of dough. Can be adjusted during operation.

Continuous production

The SD600 Dough Divider is a high quality and robust piece of machinery. Strong materials and smart lubrication systems to get long life out of the machine.

Powerful Touch Panel

Flour Duster

Non-stick coating on cone

Non-stick coating on cone and tracks for ultimate rounding. Dough does not stick as well which makes it easy to clean.

Control Panel

User-friendly, movable control panel, easy to learn and to make adjustments.

Flexible and Modular design

Modular and flexible design. Can be expanded. Up to 1128 effective pockets as standard. Larger proofers on request.

UV-lighting

UV-lighting inside the IPP Intermdidate pocket proofer with on / off function.

Common E-Stop

Common emergency stop - stop all bread line components with any emergency stop in the bread line.

Specifications

Technical Specifications

Capacity: Up to 4500 pieces/hour.

Subject to dough piece weight and characteristics.

Weight range: 100-1500 g.

Subject to dough characteristics.

Proofing time depending on capacity pcs/h and size of Intermediate Pocket Proofer - IPP.

Fuse (amp): 30A.

Power supply: 10 kW.

Based on components set-up.