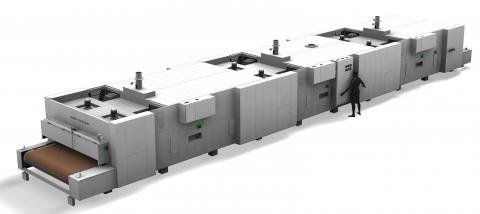

Indirect Gas Heated Tunnel Oven

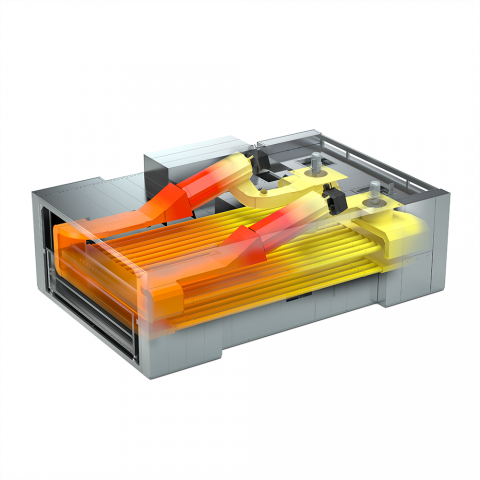

The Sveba Dahlen indirect fired gas tunnel oven offers a unique flexibility and capability for producing a wide variety of products. The tunnel oven is built on a concept where each zone has two Weishaupt™ gas burners heating the air and distributing it to the top and the bottom of the oven through heat exchangers. Using separate burners for top and bottom provides individual temperature settings for top- and bottom heat and by that optimal temperature control and fast reaction time, giving more flexibility compared to a traditional singel burner oven. Each oven zone consists of a number of prefabricated modules (each 2.2 m long) that are easy to transport and install. Additional zones can be added if more capacity is needed. Indirect gas (oil) heated ovens can be used up to 280°C. Available belt widths are 2.1 m (2.2 m*), 2.5 m (2.6 m*), 3.0 m (3.1 m*). * Up to certain length.

Features

Separate burners for top and bottom heat

By using separate burners for top and bottom heat the oven becomes more easy to regulate and the oven also reacts much faster. This way the tunnel oven is much more flexible compared to a traditional single burner oven.

Zones

Each zone in the tunnel oven is controlled independently of each other since the temperature is set in each zone just like in an electrically heated oven. There is no need to regulate the tunnel oven by use of dampers.

Energy efficient

To receive the lowest possible energy consumption in a gas oven the patented Sveba Dahlen indirect heated tunnel oven use multi burner system for heating (one burner for top-heat and one for bottom heat, in each zone). This means that power is only used in the different zones when and where it is needed.

Reliable

A traditional oven cannot be run if the burner goes out, with our oven its still possible to produce since we use multiple burners. This makes the oven very reliable.

Key features

Oven belts

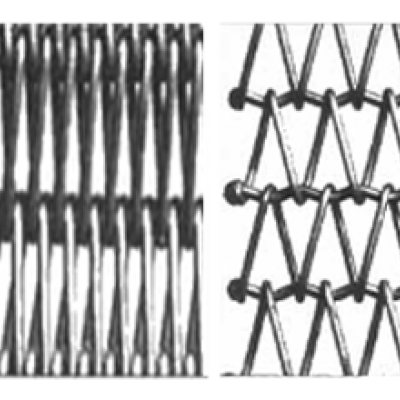

Available belts for Gas Tunnel Ovens:

Left: Tight wire mesh belt for free standing bread.

Right: Open wire mesh belt for tin breads and trays.

Unique and patented heat regulation

Unique and patented heat regulation with 2 burners per zone, one for top and one for bottom heat. Allows for better results due to a more exact temperature regulation and energy efficiency.

Control panel with touch screen

The HMI control panel with touch screen is easy to overview and operate. Control the top and bottom heat in all zones, recipes, alarms and more.