Very flexible make-up systems for bread production always adapted to the actual bread capacity, intermediate proofing time and bread type and shape

Specially adapted industrial bakery machines

Sveba Dahlen and Glimek offers solutions for most kinds of industrial bakeries. From dough make-up lines to belt proofers and tunnel ovens. In many cases the machines get special executions to fit the customers production. Our extensive experience and our aim is to always find the correct solution for our customers. With great flexibility and experience we know that we can offer the right solutions for most bakeries.

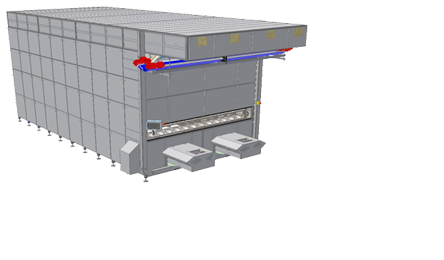

Adapted to fulfill the customers needs!

Below is an example of a customer adapted Intermediate Pocket Proofer XL.

12 pockets in each swing, more than 3700 active pockets and approx. 5000 dough balls/hour at proofing time 45 minutes.

Industrial Mixers

Sveba Dahlen offers industrial mixers and mixing systems in many different executions, spiral mixers with removable bowl and also mixers with a bottom discharge system. Mixers for larger capacities than 200 kg on request.

Bowl Lift

Bowl Lift always adapted to the removable bowl size and desired tipping direction according to layout. Standard is tipping either left or right. Possibility to also be made for straight forward tipping.

Bulk Hopper

The Bulk Hopper creates an even level in the divider hopper which gives better weight and accuracy. The photocell controlled portioning system gives automatic feeding into the divider. The uncomplicated design results in a reliable operation and less risk of production loss.

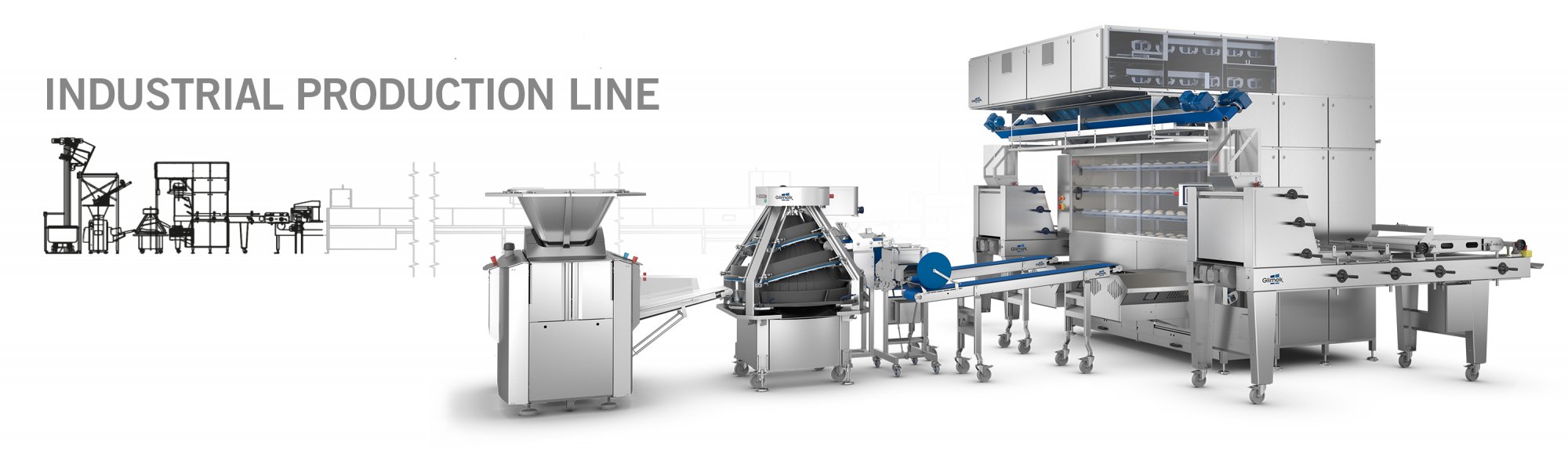

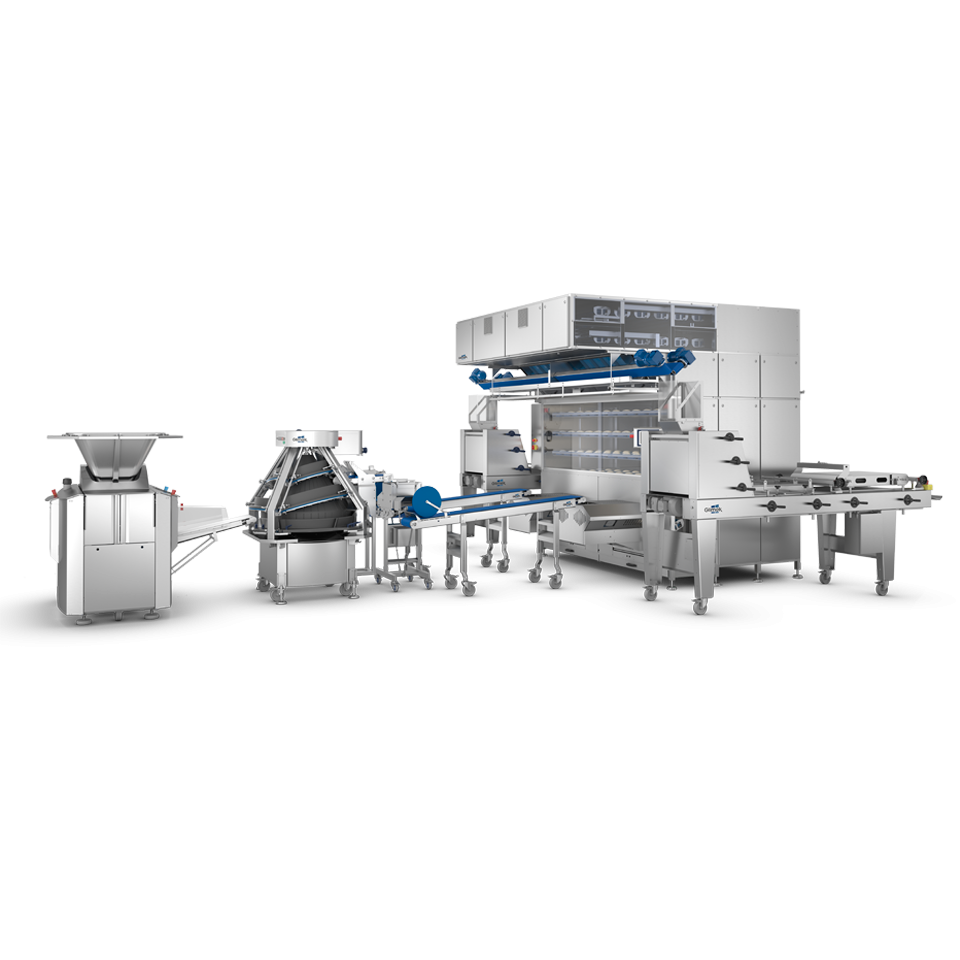

Industrial Make-up System

Very flexible make-up systems for bread production always adapted to the actual bread capacity, intermediate proofing time and bread type and shape. The line is mostly made of stainless steel and is developed in order to withstand continual operation and the industry’s stringent hygienic requirements.

See Examples of a Industrial Make-up Line compnents below.

For more examples - click here.

Dough Divider - SD600

A stainless multi pocket dough divider in 3-pocket or 2/4-pocket execution. Stepless adjustable dough pressure, adjustable while running. Robust chassis for high industrial production.

• Weight range, two versions: 150-1000 g as 3-pocket and 250-1700 / 100-700 g as 2/4-pocket.

• Capacity 1500-4500 pcs/h as 3-pocket, 2000-6000 pcs/h as 4-pocket and 1000-3000 pcs/h as 2-pocket (the measuring pistons are easily connected two and two).

Conical Rounder - CR600

A very flexible conical rounder for all kind of bakeries, suitable for most types of dough. Two individually adjustable rounding sections processes the dough for ultimate rounding and an optimal result.

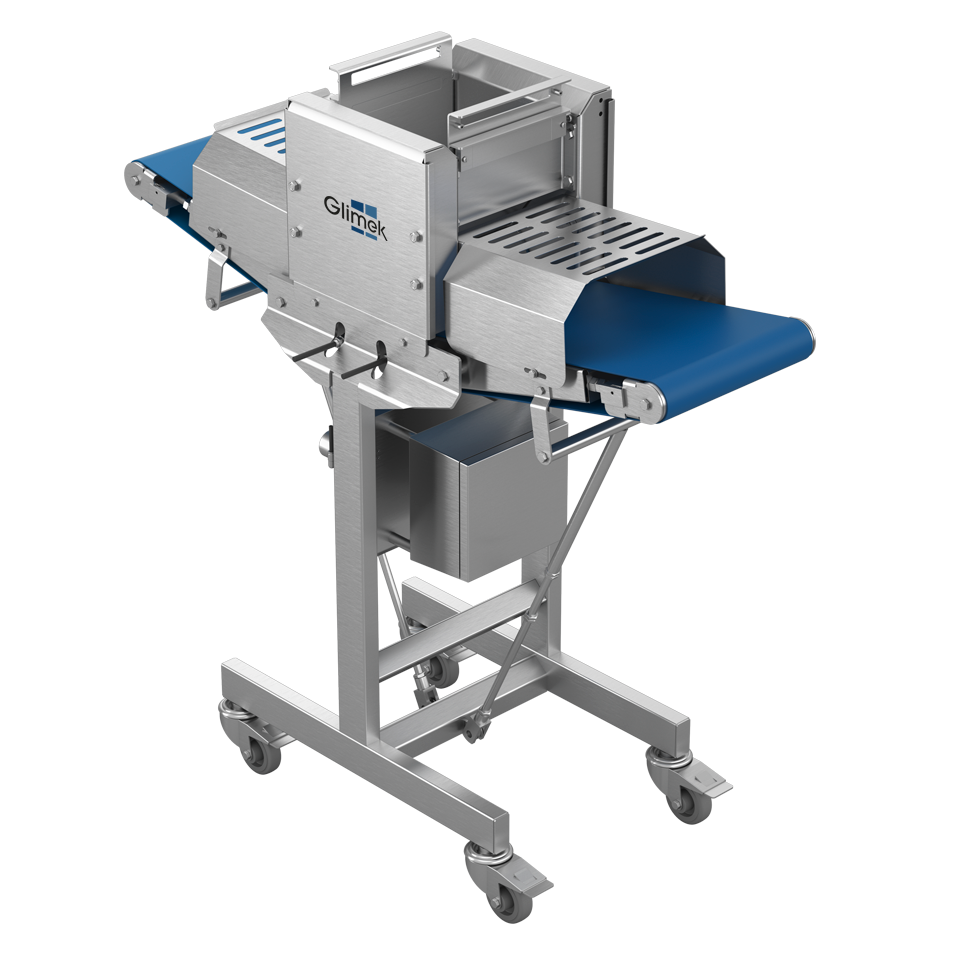

Dough Piece Separator

The DPS Dough Piece Separator, divides the line into two lines to increase the capacity of the bread line. Easy to install and to move.

• Required for increased capacity, up to 4500 pcs/hour.

• Hygienic belt and materials, easy to clean.

Belt Conveyor - BC250

The BC250 Belt Conveyor, transports the dough from the Dough Piece Seperator to the Intermediate Pocket Proofer. Easy to move and clean.

• Gives an opportunity for a final visual review of the dough.

• Hygienic belt and materials, easy to clean.

Intermediate Pocket Proofer - IPP1270

One of the most flexible pocket proofers on the market. For 6, 8, 10 or 12 pockets. Modulated for easy adaption in height and depth, available in standard models from 132 up to 1128 effective pockets. Solid construction in stainless steel materials.

• Stainless steel execution - easy to keep clean.

• Flexible layout - choice of infeed position.

• Weight range 100-1500 g.

• 4 different infeed systems. Capacity up to 1200, 1800, 3000 or 4500 pieces/hour.

• Modular layout, enlarge the IPP if longer resting time is needed.

Moulder - MO881

The MO881 Moulder, is a robust heavy duty moulder for use in industrial bakeries. Triple moulding head, curling net and double pressure boards.

• Easy to operate.

• Easy to set up for a good final moulding result.

• Dual pressure boards enables industrial production.

• Capacity up to 3600 pcs/h.

• Weight range 30-1800 g.